Over the years, several customers have requested information on how best to remove the Serviwrap or Maflowrap PVC/bitumen tape from a wrapped pipe. They are looking either to refurbish the pipe or modify the pipe run and are considering ways to clear the existing pipe protection.

Over the years, several customers have requested information on how best to remove the Serviwrap or Maflowrap PVC/bitumen tape from a wrapped pipe. They are looking either to refurbish the pipe or modify the pipe run and are considering ways to clear the existing pipe protection.

Whilst this is an understandable request, it is not the easiest task to undertake because a key property of the Serviwrap and Maflowrap PVC/bitumen tape systems is that they adhere extremely well to pipes and are designed not to be removed. However, our recommendation on how best to undertake this operation is based on several factors:

- The size of the pipe

- Pipe diameters up to 300mm typically have a thinner PVC-backed tape and lower adhesion levels, plus tape widths are usually 150mm max. All these factors allow easier removal.

- Pipe diameters above 300mm typically have thicker backed tapes with high adhesion levels and often have been machine wrapped with additional contraction adhesion.

- The accessibility of the coated service – in a trench or on surface

- If the pipe is to remain in the trench during the removal, access to the pipe will be constricted and additional health and safety concerns must be followed for working in a restrictive space. These protocols may exclude the use of volatile substances, such as xylene and white spirit.

- The amount of pipe surface to be exposed

- If the removal of tape is only on a small section, simple manual removal is the best option; however, if the area involved is extensive, possible purchase of induction heaters, etc., will be cost effective.

- The length of time the coating has been installed

- Bitumen adhesive, whilst never fully solidifying, does harden with age. A coating applied within a 24-month period still will have a comparatively soft adhesive that will not be easily removed via blasting; on the other hand, a coating that has been present for over ten years often can be removed via a sand or grit blaster.

- The condition of the coating

- If the pipe has been exposed to sunlight for a protracted period, the PVC will have become brittle and is easier to remove; however, the bitumen adhesive still will be adhered to the pipe.

The key to the removal of the Serviwrap/Maflowrap tape is to gain access to the adhesive. Listed below are a couple of typical situations and methods for tape removal.

Example 1- pipe accessible on surface

- 6m length to be cleared

- wrapping condition is good

- wrapped five years ago

- 200DN pipe

- Slit the PVC film longitudinally along the pipe length on the top surface.

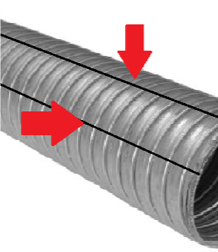

- Peel the PVC from the pipe/adhesive in a cigarette paper manner. This normally can be undertaken with pipes up to 100DN without any additional slitting. If the tape is still bonding tightly, slit again longitudinally along both pipe widths and attempt to peel these smaller sections (see arrows below).

- If the tape continues to adhere to the pipe, work along the length of the pipe, slitting the PVC film laterally around the circumference every 150mm-250mm along the pipe.

- With the PVC removed, you now have access to the adhesive. Depending on the stiffness of the adhesive, first try to scrape the bitumen off the pipe manually, using a metal-edged, two-inch width scrapper. Whilst this is unlikely to be 100% successful, it may at least allow you to remove a percentage of the softer adhesive.

- Three standard options are available for the removal of the balance of the material.

- Wipe the adhesive surface with a solution, such as (a) rubbing alcohol, (b) WD-40 or ultimately a solvent, such as (c) xylene or white spirit (when local pertinent health and safety rules permit this, of course). Allow the bitumen to soften and then scrape it off.

- Heat the surface with an open flame (when local pertinent health and safety rules allow this again). When the bitumen softens it can be removed. Note that it is not advisable to allow the bitumen to smoke or burn due to harmful vapours and the possibility of damaging any underlying coatings.

- Depending on the amount of adhesive still adhering to the pipe, it is possible to attempt to use a grit blaster to clear or at least break up the bitumen layer.

- 600DN pipe

- wrapped ten years ago

- wrapping condition is good

- 6m length to be cleared

- pipe accessible on surface

Due to the scale of this task, I would recommend the purchase or hire of an induction heater such that we are looking to weaken the bond between the adhesive and the pipe and then either unwrap the tape or remove sections of the tape in a similar manner as listed in example 1 parts (a) through (c) above.

Depending on the size of the induction heater available and hence the area and depth that can be warmed, first try with the PVC still attached. If the heat is not getting to the pipe bond surface, it may be necessary either to obtain a larger heater or to remove the PVC outer layer prior to using the induction heater.

If you are looking refurbish the pipe or modify the pipe run and you still have questions, you can always contact us.

.png)

.png)