One of the critical elements in a successful paving project is the asphalt mix design. Another term...

Benefits of Polymer Mix Modifiers to Asphalt

The use of polymer modified asphalt is commonly accepted by numerous Departments of Transportation, Bridge, and Highway Authorities in the United States. Polymer modifiers provide asphalt pavement with enhanced flexural properties, resistance to rutting and shoving, as well as, improved overall performance at higher and lower temperature ranges than typical unmodified asphalt concrete. There are two types of polymers, dry or liquid that can be used to modify asphalt.

The use of polymer modified asphalt is commonly accepted by numerous Departments of Transportation, Bridge, and Highway Authorities in the United States. Polymer modifiers provide asphalt pavement with enhanced flexural properties, resistance to rutting and shoving, as well as, improved overall performance at higher and lower temperature ranges than typical unmodified asphalt concrete. There are two types of polymers, dry or liquid that can be used to modify asphalt.

Liquid asphalt has a range of uses in both commercial and residential applications. Asphalt concrete or as it is commonly known as, asphalt binder, is used in the manufacturing of asphalt pavement. Liquid asphalt is distilled from petroleum crude oil and through a process known as catalytic cracking, crude petroleum is distilled into lighter fractions or products. Gasoline is one of the most widely known products while one of the heavier fractions of crude petroleum is liquid asphalt.

Liquid asphalt has strong binding characteristics and is added to stone aggregates, in various gradations, along with sand to form asphalt concrete. Asphalt concrete has been used for well over a hundred years to pave roads. But, as traffic volume and live loading have significantly increased over time, the need for a longer service life for asphalt pavement is required. It was this demand that led to the development of polymers to improve the performance of asphalt surfaces or wearing courses.

The Function of Polymers

Typically, liquid polymers are manufactured and added to the liquid binder, where it is stored in bulk tank farms. The polymer-modified binder is subsequently transported to an asphalt plant for use. The polymer-modified binder improves flexural fatigue (resistance to cracking) and rut and shove resistance.

Related article: Rutting & Shoving: Why is This a Problem for Bridge Decks and Roadways

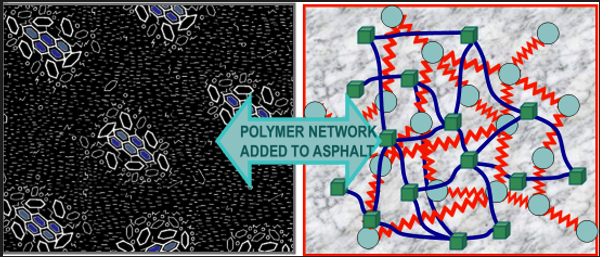

Performance data, based on AASHTO Standards, is used to determine the binder’s Performance Grading (PG). In addition to providing improved flexural fatigue and rut and shove properties, the polymer enhances the waterproofing properties of the asphalt overlay. A dry polymer is added to the asphalt mix at around 2%-3% by weight to an asphalt mix at an asphalt plant. This additive provides a polymer “network” that effectively reduces air voids in the mix to less than 4% and, in many mixes, down to 1% or 2%. Low air void percentages in an asphalt mix provide very low hydraulic conductivity, equal to or less than 1 x10 ˉ⁷cm/sec. This data was obtained as per ASTM D5084. The result is a waterproof asphalt surface course.

|

|

Figure: Polymer Modifiers fill the void spaces in asphalt mixes |

A waterproof asphalt overlay, on both steel and concrete bridges, is important to the performance and longevity of asphalt because it protects the bridge deck from moisture permeation, chloride contamination, and corrosion. The detrimental effects of corrosion on the service life of steel and concrete are well documented and understood.

Related article: How to Produce a Top-Quality & Durable Asphalt Overlay

As discussed, polymer modifier provides significant enhancements to the performance properties of liquid asphalt and can increase a standard PG 64-22 at least three grades in high temperature and at least one “bump” on the low temperature. There are maintenance advantages in using a dry additive instead of a liquid one. Heated storage tanks are not necessary with dry additives and the quantity of dry polymer can be ordered specifically to meet the tonnage required in the project scope of work.

Chase Corporation makes a polymer additive to provide these performance additives. Rosphalt R50 is manufacturing by Chase Corporation for these applications. Reach out can assist with the solutions on your projects.