Not all waterproofing systems perform the same under real-world stress. CIM 1000 stands apart from rigid epoxies and asphaltic coatings with its elastomeric flexibility, strong adhesion across tough substrates, and extremely low permeability. With crack-bridging up to ~400% elongation, seamless liquid-applied application, and NSF/ANSI 61 potable assemblies, CIM 1000 delivers reliable protection where competitors often fail.

Topics: Concrete Waterproofing, Water Tank

Stricter VOC rules—and the need for healthier, faster jobsites—are pushing owners to zero-VOC waterproofing. CIM’s 100% solids membranes deliver compliance without the solvent odors, while maintaining long-term, elastomeric performance and very low permeability. Use CIM ECO 1000 for zero-VOC, low-odor indoor work, CIM ECO 1061 where NSF/ANSI 61 potable approval is required, and CIM 1000 TG for vertical/overhead areas in potable assemblies—paired with moisture-tolerant, VOC-compliant primers. The result: safer installs, quicker turnarounds, and a seamless barrier that bridges cracks and handles complex details.

Topics: Concrete Waterproofing, Water Tank

Introducing CIM ECO 1061: Fast Cure, Zero VOC, Potable Water Approved.

At CIM Industries, performance and reliability have always defined our products. The latest addition to our liquid coatings line, CIM ECO 1061, not only sets a new standard for potable water protection but also for environmental sustainability. With Zero VOCs, ANSI/NSF61 potable-water approval, LEED certification, and an industry-leading

return-to-service time of 72 hours, CIM ECO 1061 enables utilities and contractors to cut downtime, accelerate project schedules, and put tanks back in operation faster.

Topics: Concrete Waterproofing, Water Tank

Choosing the right waterproofing membrane is crucial to ensuring your commercial or industrial project stands strong against water intrusion for decades. Whether protecting parking decks, water/wastewater tanks, tunnels, or plazas, understanding membrane types, applications, and specification criteria enables successful waterproofing.

This guide compares liquid-applied and sheet membranes, explains CIM’s product lineup for various substrates and environments, and shares installation and QA best practices to avoid costly errors.

Topics: Concrete Waterproofing, Water Tank

Understanding Waterproofing Warranties: Updated Guidance from CIM

Peace of mind starts with the right protection, and the right partner.

When it comes to waterproofing systems, a warranty is more than paperwork, it's a manufacturer’s formal promise that the product will perform as intended. It assures the building owner that the materials are free from defects and provides a path forward if issues arise. Most warranties are signed by both the building owner and a representative of the product manufacturer and are designed to build confidence in long-term performance and durability.

Topics: Concrete coating, CIM Industry, CIM Concrete Waterproofing, Concrete Waterproofing, Waterproofing tiles

Explaining LEED Ratings and Credit-Earning Materials

As we step into the twenty-first century, the design, construction, and maintenance of industrial and commercial structures, residential homes and buildings, and our environment continue to be a focus. With a growing emphasis on sustainability, the manufacture and use of eco-friendly construction materials are not just receiving visibility but are becoming a crucial aspect in the architectural and engineering design communities. This is particularly true for the structural elements within a project’s design scope of work and the potentially impacted surrounding environment: recreational areas, wetlands, rivers, and streams.

Topics: VOC emissions, LEED

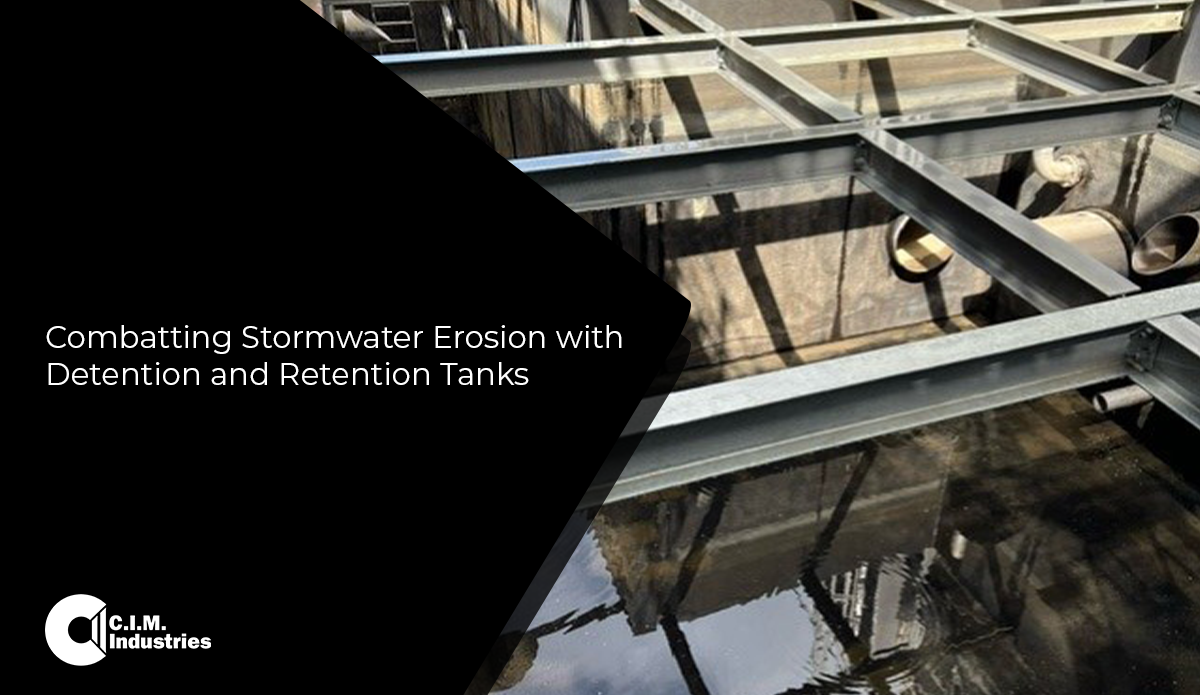

Combatting Stormwater Erosion with Detention and Retention Tanks

Erosion occurs when winds or water interact with soil and rock, causing the affected earth to wear away. The most common example of erosion is at the beach, where tide patterns cause water to move up onto the shore and away from the shore, dragging the sand out to sea and changing the landscape.

To remedy this, communities have built retaining walls that follow parallel to the shoreline to help stop surface and subsurface erosion. While the beach may be the most thought of place where erosion occurs, it also happens onshore. Torrential downpours can wreak havoc by causing flooding and extreme soil erosion. Like beach erosion, there are ways to mitigate this issue.

Topics: Concrete Waterproofing, Water Tank

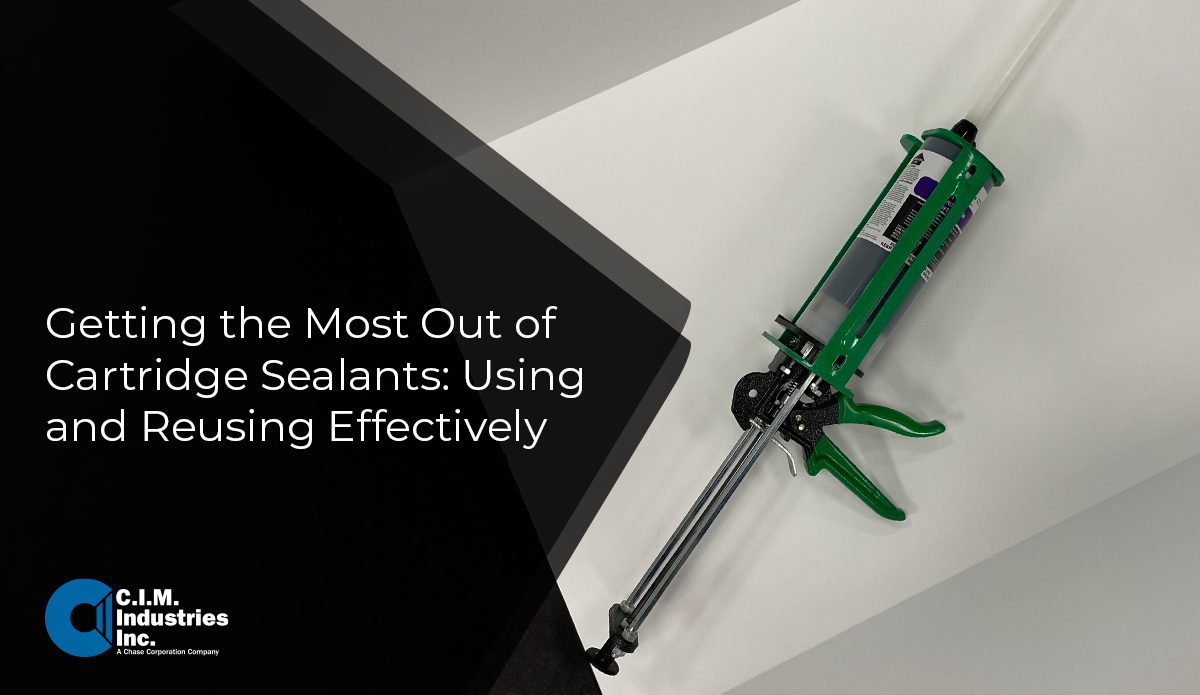

Getting the Most Out of Cartridge Sealants: Using and Reusing Effectively

Joint sealants are typically available in cartridges (either single or dual components). Each cartridge style is designed for specific applications and environments. Generally, cartridges are ideal for small applications such as penetrations, joints, cracks, and many other repairs requiring waterproofing or chemical containment. Partially used cartridges can be stored and reused later. Instant mixing and dispensing of sealants are often performed via a hand, air, or battery-powered caulking gun.

In this article, we'll discuss:

- The advantages of using cartridges over other application methods

- The basic differences between single-component and dual-component cartridge sealants

- How to set up a sealant dispensing gun

- How to store a partially used sealant cartridge

Topics: CIM 1000 Premix, Concrete Sealant

Mixing Multi-Component Coatings Materials: Induction Time and Pot Life

Understanding and following the manufacturer's written guidelines and technical data sheets are essential to achieve the best application of coating possible. Focusing on critical factors, such as choosing the right type of coating, surface preparation, and application methods will ensure everything is done correctly. By doing so, you can be confident you'll get the desired results and have a coating that looks great and performs well in its environment.

Here, we'll discuss the importance of adequately mixing multi-component coatings before application. When mixing single-component coatings, the applicator brings them to a uniform color or condition. However, when mixing multi-component coatings, the process is more involved.

Let's take a look.

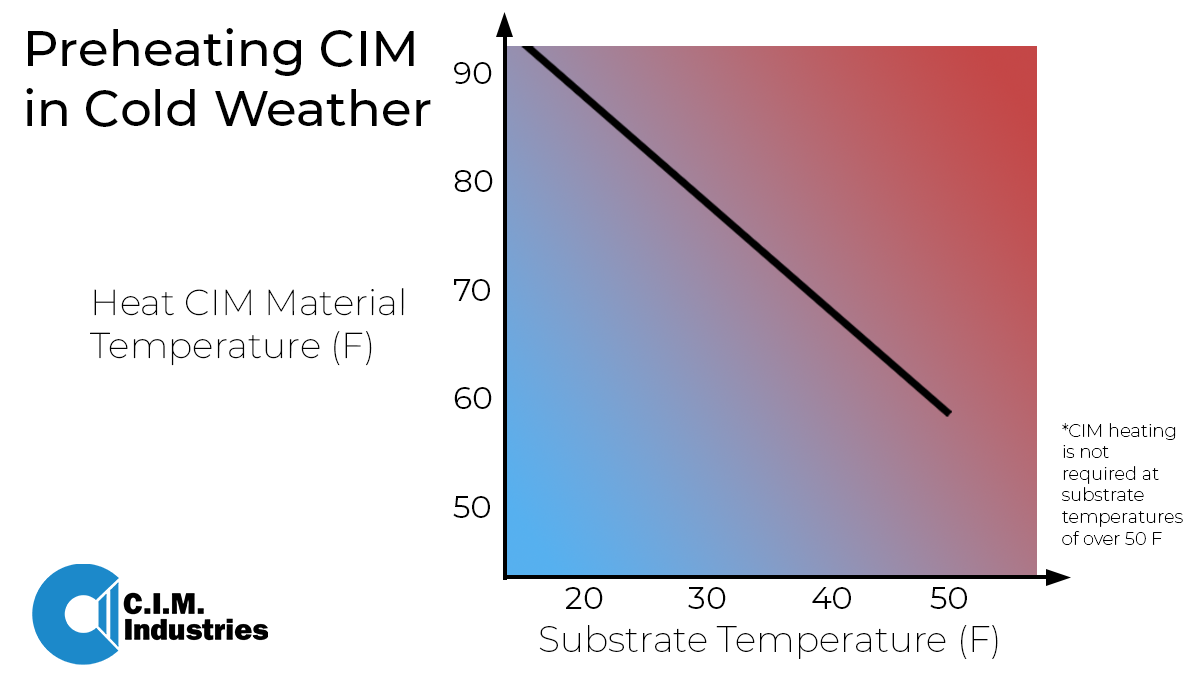

The Ultimate Guide to Applying CIM Membranes in Cold Weather

Winter is here, and you may have surfaces that need coverage despite the cold weather. It is important to understand the environmental conditions and limitations of cold weather application before proceeding with the application of any coating.

Review the cold-weather fluid-applied application instructions for detailed application guidelines. However, the application guidelines alone will not paint the full picture. Follow along for professional advice on applying in the (cold) field.

Topics: conformal coating application, CIM Cold Weather Application

.png?width=650&height=278&name=CIM%20Chase%20logoK_301C%20(3).png)