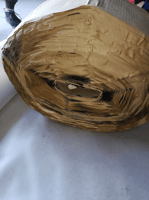

Defects in pipeline coatings and tapes can happen for a number of reasons, all of which can result...

9 Questions to Ask When Selecting the Proper Protective Coating for Your Pipeline

No single coating that can protect every pipeline from corrosion for all conditions. Finding the appropriate coating for each application can be challenging. But asking the right questions can help you find the product offering the best long-term performance.

No single coating that can protect every pipeline from corrosion for all conditions. Finding the appropriate coating for each application can be challenging. But asking the right questions can help you find the product offering the best long-term performance.

To identify a coating for the job, understanding the project requirements and performance needs are key parts of the process. Here is a list of questions you should ask:

- Atmospheric condition: Is the application above or below ground?

- If above ground, will the coating be exposed to UV?

- If buried, what is the condition of the soils or back fill? How quickly will the pipeline be back filled?

- Condition of the substrate or the existing coating. Which surface preparations are allowable methods?

- Is the existing coating well-bonded, and will it accept subsequent coatings?

- Are there limitations as to which surface preparation methods, such as sandblasting or grinding, are allowed at the site?

- Is the pipe dry or can it be dried?

- What is the diameter of the pipe?

- What is the service temperature of the pipe?

- What are the environmental conditions that will be present during the application?

- temperature

- relative humidity

- other?

- Are there irregular shapes or details (flanges, tees, ) in the pipe?

- Is there an atmospheric “transition” area from below to above ground? Is additional mechanical protection needed for protection at the freeze/thaw line?

- Is protection needed from lawn mowers, string trimmers, and the like?

- Will the coating be applied by maintenance staff or an industrial coating contractor?

The responses to these questions should be evaluated to determine the proper coating for the application.

Contact Chase Corporation’s team of technical consultants to assist you with the evaluation and provide pipeline product information that meets your specific application needs.