Protect Thermite Welds On A Cathodic Protection System

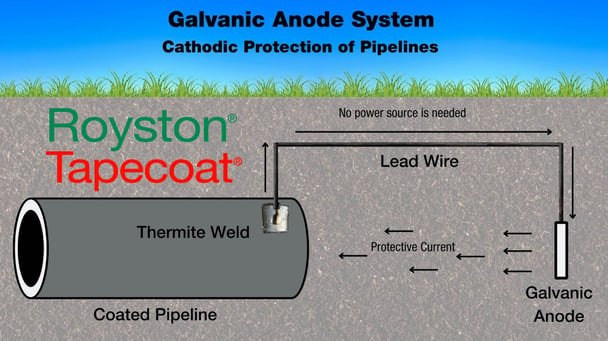

To understand the importance of protecting thermite welds, we must first identify their location in a cathodic protection system. Cathodic protection can be best described as the method used to control the corrosion of a metal surface by making it the cathode of an electrochemical process. The type of protection connects the protected metal structure to a more easily corroded sacrificial metal which acts as the anode. The objective is for the sacrificial metal to corrode instead of the protected metal.

Soil resistivity, structure size, and past corrosion history are factors to consider when selecting a cathodic protection system. Cathodic protection systems are applied to:

- Water or fuel pipelines

- Steel pier piles

- Steel

- Ships

- Offshore oil platforms

- Onshore oil well casings

Galvanic (sacrificial) anodes or impressed current are necessary for corrosion protection. This article will focus on corrosion protection of pipelines using galvanic anodes and how to protect the thermite welds.

Galvanic Anode Corrosion Protection System

Figure 1: Galvanic Anode System

Factors to consider when deciding on a cathodic protection system are often grouped into the following categories:

- Structural Details

- Dimensions

- Pipe size

- Wire size

- Specified materials or products utilized for coating the system

- Tapes

- Liquid coatings

- Thermite weld caps

- Cased crossings (carrier pipe within an encasement pipe)

- Availability of AC power

- Dimensions

- Environmental Conditions

- Details of soil strata/terrain

- Presence of foreign metallic structures

- Stray electrical current conditions

- Location limits

- Climate

- Operational Parameters

- Operating temperature

- History of corrosive areas

- Future maintenance/updates of structure

Related Article: What to Consider When Backfilling a Pipeline

Thermite Weld Protection

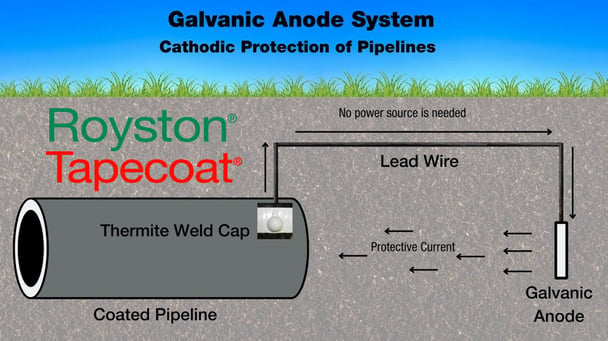

A thermite weld is a method of attaching a copper conductor cable to steel or cast iron. This process involves connecting cathodic protection cables to pipelines, including test leads and negative and bonding wires. The welding process uses a high-temperature reaction charge of powdered copper oxide and aluminum which, when ignited, produces aluminum oxide and super-heated copper. A protective cap or pad is then applied over the thermite weld to provide additional corrosion protection.

Figure 2: Thermite Weld Protection on Steel Pipe

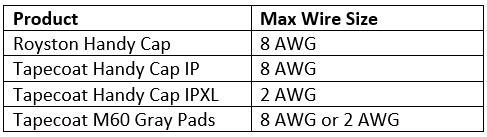

Wire Size Matters

The diameter of the pipe and wire gauge size are two principal factors to consider when determining how to protect the thermite welds on a cathodic protection system. An 8-AWG wire is commonly used on small to medium diameter pipes, while a 2-AWG wire is typical on medium to large diameter pipes. It is essential to review all agency specifications and manufacturer’s written instructions to confirm which thermite weld protection product is suitable for the sized wire.

Thermite Weld Caps and Pad Selection Chart

A failed coating can lead to corrosion problems that prevent the cathodic protection systems from working properly. Selecting the right size thermite weld cap is the best approach for minimizing coating failures.

Avoiding Corrosion

Corrosion occurs when an anode, cathode, return path, and electrolyte are present. By removing one or more of these components, we can prevent corrosion. However, this is not always possible. Identifying areas and conditions where corrosion is likely to occur can guide us in selecting which cathodic protection system to use, either galvanic anodes or impressed current. When choosing a galvanic anode system, remember that thermite welds require protection too.

Tapecoat and Royston tape coating systems provide corrosion protection to critical pipeline infrastructure. Our technical representatives can assist with product information to meet your coating needs. Please contact us.