High-temperature corrosion protection coatings are developed to meet the harsh environmental...

Understanding the Impact of Tape Failure on Pipeline Service Life

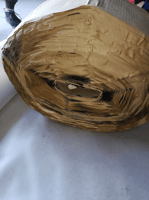

This Summer, the Chase Pipeline team was asked to come out and assist in recoating a non-potable water pipeline in Eastern Saudi Arabia. The pipe was previously coated with a competitor’s multilayer tape and had failed prematurely. The pipeline in question corroded; this is normal. No tape is expected to last thousands of years.

However, in the conditions seen in Saudi Arabia, the double-layer tape underperformed against expectations. The tape that was previously used had an equivalent thickness to our single-layer wrap. That means each of the two coats of tape could only individually protect half as well as our extra-thick coat.

There are plenty of reasons to choose double-layer wrap; that is not in question. But we were looking at unimaginable heat and harsh, battering sand. Under these intense pressures, the double-layer wrap could not hold up.

There are a few reasons why the double layer wrap may have failed.

- With twice the wrapping, there is twice the likelihood for application errors, like tenting or voids

- Twice the amount of wrap needs twice the surface preparation. If both surfaces (the pipe and the primary layer of tape) are not sufficiently cleaned and preserved (tough to do with sandstorms), clean adhesion may not be attained. For this reason, we highly recommend surface testing before application.

Regardless, premature failure of the tape occurred. The layers cracked, exposing the pipeline to corroding forces. As expected, this caused the pipeline to rust and break. Ironically, the pipeline itself broke in a way that slapping some tape over could not fix. See for yourself:

Protecting Against Pipeline Corrosion

Not all rust is a death sentence or a “holiday”. There are instances where a rewrap of fresh tape could save the pipe from rupture. In this instance, however, the pipe was too corroded to support the internal pressure. Entire sections of the pipeline were replaced. If the cost of quality, durable tape seems prohibitively expensive, then I ask you to imagine the cost of thousands of meters of pipeline. Needless to say, it’s a big expense.

It’s worth noting that there are phenomenal cathodic protection systems that similarly help protect against corrosion. These use an ingenious electrochemical design to naturally guide corroding forces to a sacrificial anode. We have a more detailed breakdown in a separate blog post.

Soil Stress and Pipeline Damage

We should also discuss soil stress. For underground pipelines, soil stress is lethal. This refers to the natural shifting of dirt and other substrates underground. For pipes, this shifting wears like sandpaper. In a sandy desert, that comparison is a little more direct. Pipes are tough. This type of consistent, long-term degradation can break down even the toughest surfaces. Like how—with time—a simple stream can slowly erode the earth and form a roaring river, soil stresses can similarly wear down the toughest steel.

Tape needs to protect from corroding forces, and it also must protect from the exterior damage and strain soil stresses cause. Double wrapping tape helps add protection, but so does having a single-layer wrap with equivalent thickness and protective capabilities. Extra solid single-wrap does edge out a bit better though as it creates a solid barrier of protection, not one with layers the sand can slip between—further weakening the adhesive properties of the tape.

Ultimately, the pipe was replaced and coated with Chase's single-layer Maflowrap 900 tape, a tape designed for easy application and lasting results. This particular brand is a popular choice for European and Asian operations. For similar jobs in the Americas, the M50 single-layer tape is preferred for below-grade applications. We recommend H50 for above-grade applications.

Single layer tape was the right choice for this job, and it may be the right choice for yours as well. We have a few more insights from this Saudi Arabia job site we intend to publish on our blog. The best way to know when these go live is to subscribe to our mailing list. You may also find our blog on pipe and pipeworks color code guide helpful. If you have any protective coating questions, please contact us. We are happy to assist in any way possible.