The composite industry is highly competitive and wrestles with a number of variables in production....

8 Reasons Why You Should Consider Polymeric Microspheres

(Image 1)

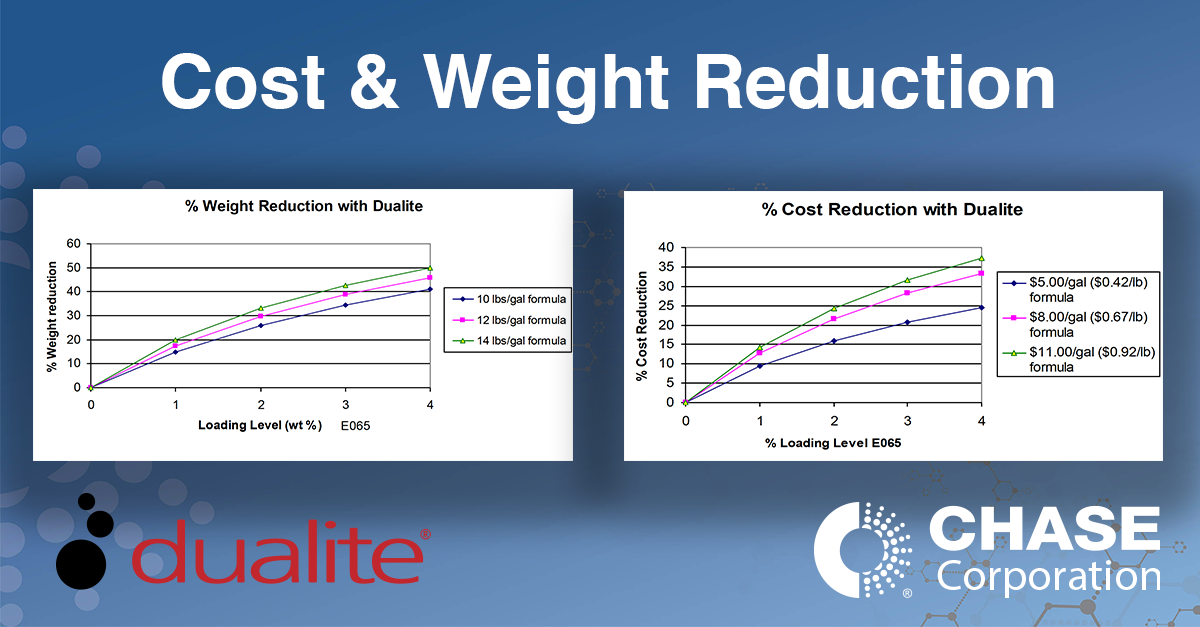

Most people are aware that polymeric microspheres can dramatically reduce the cost and weight of their formulas/products. In addition to cost and weight improvements (Image 1), there are several other benefits you can obtain when using polymeric microspheres.

Adhesives and coatings are used in various stringent environmental conditions that demand a lot from these products.

The many benefits of polymeric microspheres can lead to a product’s maximum performance.

- Reduce volatile organic compounds -Microspheres take up space and reduce the amount of resin needed in the formula. They can also impede the migration of the VOC (Volatile Organic Compound) trying to escape the resin mix.

- Reduce shrinkage – Microspheres do not shrink or absorb moisture.

- Better impact/crack resistance -- The flexible microspheres absorb impact and energy.

- Insulation Value – They create a space of air.

- Dry time – Water-based adhesives and coatings will dry quicker with microspheres since they take up more space, using less water.

- Reflective – Dualite is white in color.

- Sound dampening – Microspheres create a layer/space, absorbing noise and vibration.

- Viscosity enhancer – A small addition of microspheres can help to increase viscosity, which can also be quickly reduced with pressure.

Chase Corporation offers a variety of both expanded and unexpanded Dualite polymeric microspheres. We can assist you in choosing the best microsphere for your application, which will help you obtain your goal(s) in meeting the physical properties of your products. Contact us if you have any questions.