A common focus in wastewater treatment facilities is the maintenance and protection of the tanks in...

The Ultimate Guide to Understand Expansion Joints Types

Expansion joints are primarily designed to facilitate the movement in structures caused by temperature induced expansion and contraction. They also help extend the life of concrete structures by providing some “give” in the movement of the structure. Expansion joints can be used in parking garages, overpasses, roadways, sidewalks, piping structures and railway tracks.

There are many types of expansion joints. This guide will help you understand the differences, so you can make an informed decision for your next construction project.

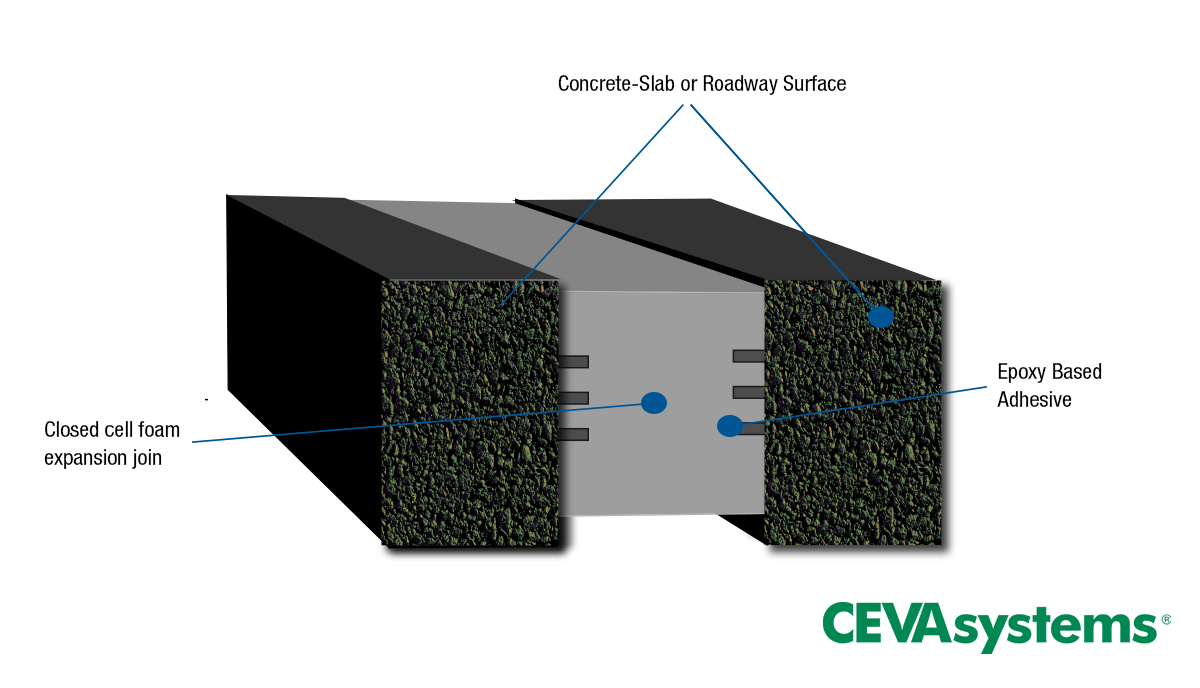

1. Foam-type Expansion Joint

There are two types of foam expansion joints: Preformed closed cell foam and Impregnated open cell foam joints.

- Closed cell foam is comprised of a low density, cross-lined Ethyl Vinyl Acetate – Polyethylene material or similar which creates a strong rubber-like material comprised of individual “cells” that sit closely together but are not connected.

- Impregnated open cell foam systems are comprised of pre-compressed, silicone and impregnated foam hybrid material that requires a silicone surface sealant which seals substrate voids.

Both systems require an epoxy adhesive which bonds the foam joint seal material to the header/substrate material.

Image: Expansion Joint offered by CEVA Systems is a closed cell foam with epoxy based adhesive

Benefits:

- Watertight, UV resistant, durable seals.

- Installed under compression preventing the seal from becoming dislodged.

- Allows for staged construction and can be custom fabricated to individual project specifications.

- 3-4-person installation team necessary for installation.

These Joints are Found on:

- Different types of applications such as:

- bridges,

- commercial buildings,

- parking decks, and

- water treatment structures

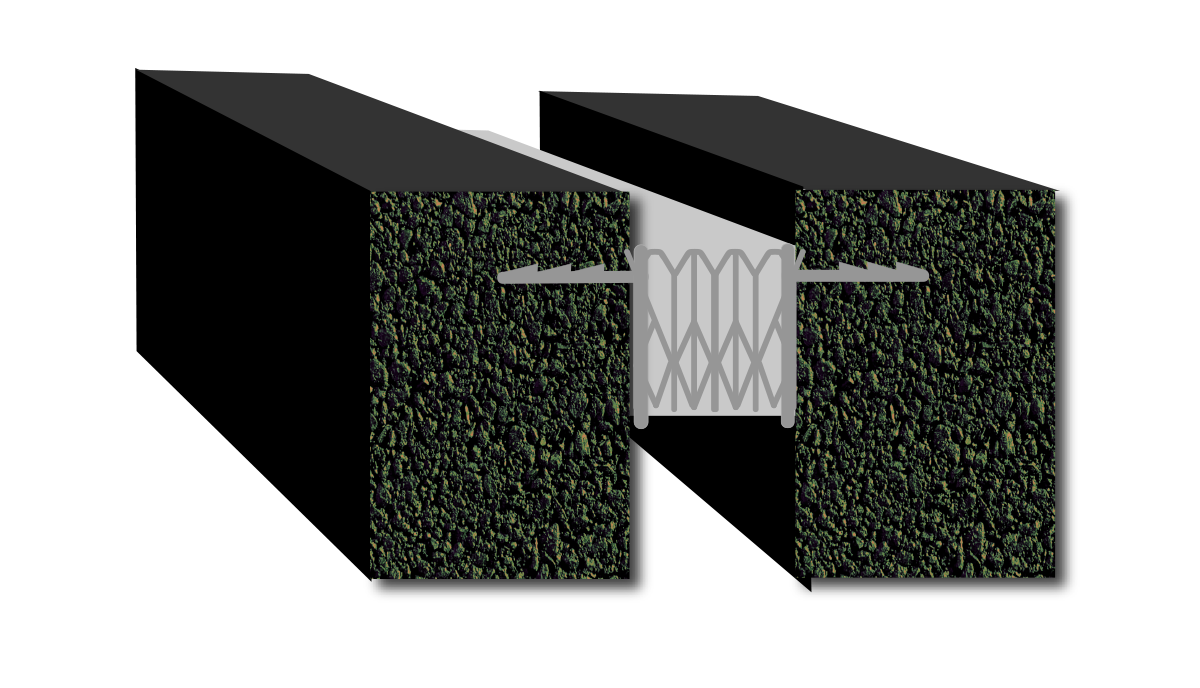

2. Compression Seal Expansion Joint

These kinds of joints are typically classified as neoprene or cellular, both of which are installed using a lubricant which also serves as an adhesive. These joints are designed to accommodate movements of less than 2 1/2” and do not permit staged construction.

Benefits:

- They can conform well to various structural configurations

These Joints are Found on:

- bridges and highways especially suited for high traffic situations.

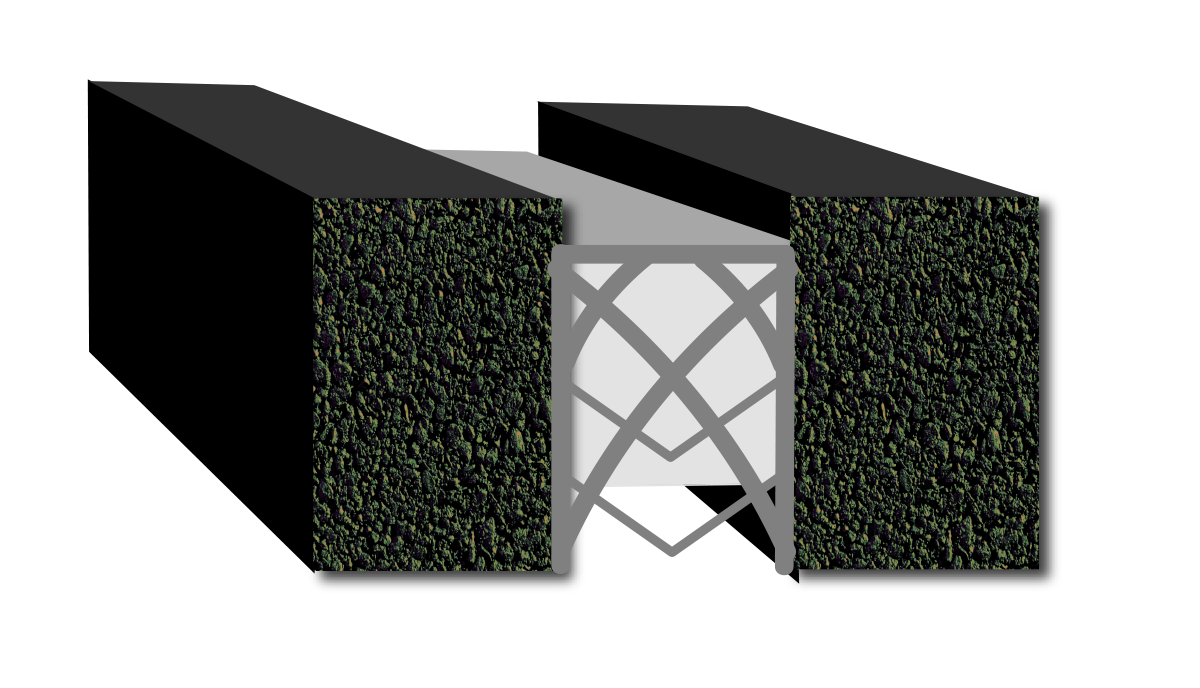

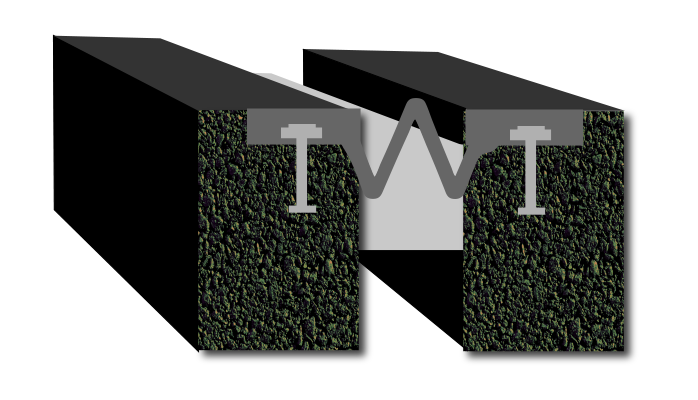

3. Winged Joint

They are typically made of thermoplastic materials; these joints behave like a compression seal but have additional “wings” incorporated to provide secure attachment. These systems require additional manpower (5-6 people) for installation and do not accommodate staged construction or customization.

Benefits:

- These are bonded into the header material for a continuous watertight system

- The embedded “wings” on this type of joint prevent the extrusion of the joint seal with movement of the substrate.

These Joints are Found on:

- Parking structures, stadiums, plazas, and other types of concrete structures where water tightness is required.

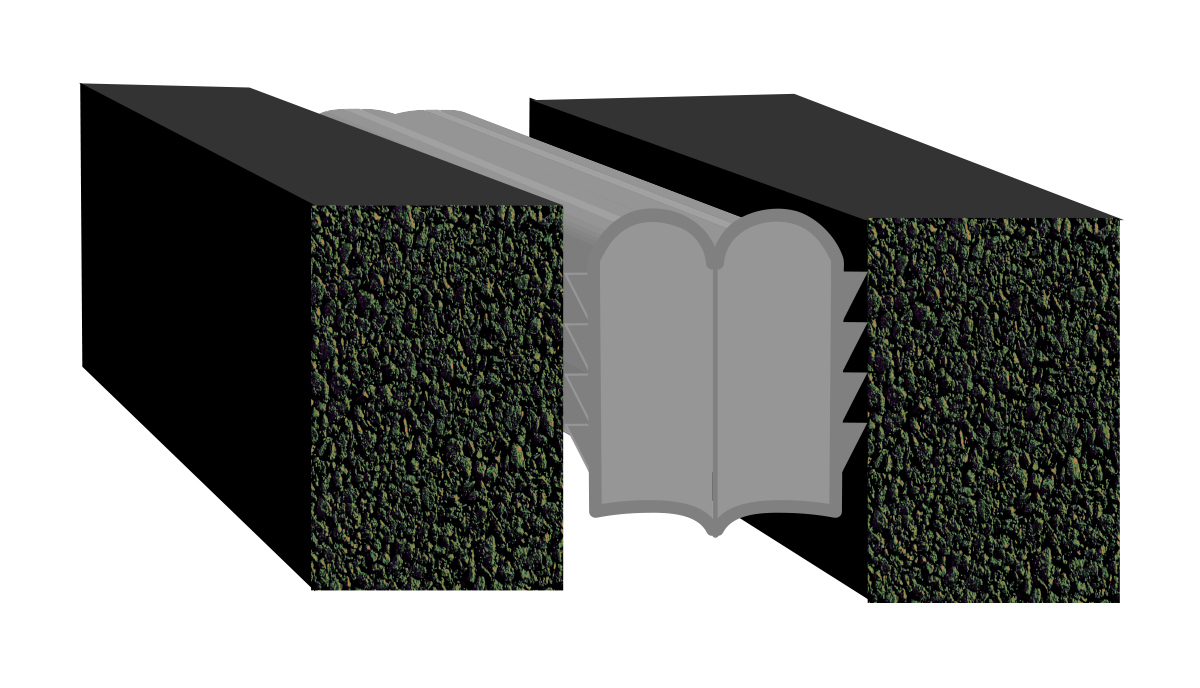

4. Inflated Expansion Joints

Made of neoprene thermoset rubber that is air pressurized and bonded in place with epoxy. These systems can also take up to 5-6-man crews for installation and do not accommodate staged construction or customization.

Benefits:

- Allows increased movement and multi-directional range.

- Compression, conforming to structural configurations, prevention from coming out of the joint.

These Joints are Found on:

- Bridges, roadways and tunnels.

5. Strip Seals

A rubber elastomeric seal mechanically locked between two steel edge members providing a watertight sealing system that is cast-in-place. Can typically accommodate movements up to 4”.

Benefits:

- Withstands freeze-thaw cycles

- Normally exhibit long service life (with proper maintenance) and high degree of water proofing.

- These types of joints are cast-in-place systems.

These Joints are Found on:

- Bridge and parking decks as well as skewed joints

Different types of expansion joints that Chase Corporation offers.

| FOAM | USES | ADVANTAGES |

|

Control joints, seismic joints, watertight gaskets |

|

|

|

Control joints, seismic joints, watertight gaskets, roof joints |

|

|

|

Control joints, seismic joints, watertight gaskets |

|

|

|

Pressure relief joints, cast in place filler, secondary seal |

|

How to Install CEVA 250 Expansion Joint

Expansion joint systems are critical to the longevity of any project. Developed in conjunction with architects, engineers and contractors, Chase Corporation’s CEVA Joint Systems provide a cost effective and easy to install solution, resulting in both labor and material cost reductions. Measuring expansion joints can be tricky, read our guide!