When designers started to plan what would become North America’s largest man-made waterfalls (World Trade Center Memorial -WTC) in New York City, they faced a number of challenges. One of the biggest concerns was how to contain vast quantities of water while preventing infiltration into underground structures.

Topics: Concrete coating, World Trade Center Memorial, Concrete Waterproofing, Concrete Sealant

Understanding Potable Water Approvals for Tank Coatings and Linings

Clean drinking water is often taken for granted. Drinking water standards are more stringent today to ensure that water is safe to drink. In 1988, NSF/ANSI 61 Drinking Water Systems Components – Health Effects standard was published. There are several laboratories certified by ANSI to test to this standard, including Underwriters Laboratories, the National Sanitation Foundation, and the Water Quality Association.

To Prime or Not to Prime… That Is the Question

Have you ever found yourself on a job site with one or more of the following conditions?

Topics: CIM Documentation, CIM Concrete Waterproofing, EMT Primer

Congratulations! You have finished installing a two-component, high-build elastomeric coating on the interior of a water detention tank. The next task is to perform a final walk-through inspection. Before we get started, it is important to know what to look for prior to the inspection. Consult the specific job specification as well as any manufacturers literature:

- Instruction guides

- Application checklists

- Specifications

- Technical data sheets

Topics: CIM Documentation, CIM Industry, CIM Concrete Waterproofing

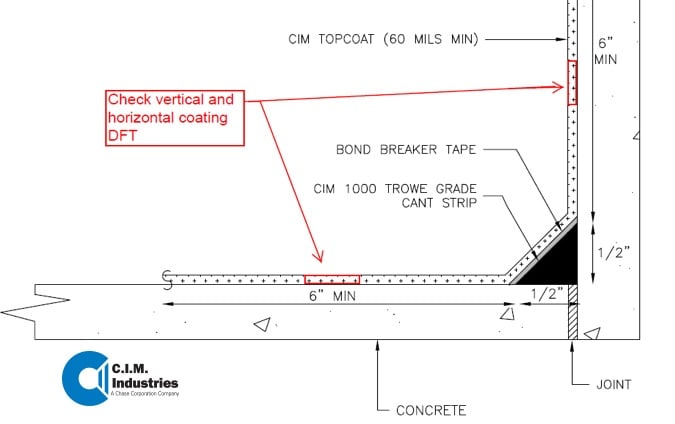

Waterproofing membranes, waterproofing coatings, and waterproof linings are terms that can be applied to a wide range of products. They can be cold-applied liquid products, hot-applied products, peel-and-stick membranes or thermoplastic linings to name a few. All these products provide a good barrier to water when used under proper circumstances. So, why do so many installations leak?

Left image: reinforcing fabric installation on a roof

The presence of leaks can almost always be attributed to poor attention to the waterproofing details, including:

Topics: CIM blog topic, waterproofing tapes

Smart Tips For Cold Weather Coating Applications That Will Save You Time

It’s common knowledge that colder temperatures can impact the curing of coatings. To achieve the optimum performance properties of the coating, special attention to the manufacturer’s application guidelines is needed.

Applications at colder temperatures, or below the manufacturer’s recommendations, require experienced contractors who are familiar with CIM products.

Topics: CIM Documentation, drying concrete, Concrete coating, CIM Cold Weather Application

How to Dry Concrete Prior to a Coating Application

Coatings fail to bond to concrete for two reasons:

- Lack of sufficient surface profile.

- Moisture in the concrete

Today, most coating manufacturers require concrete substrates to be dry (<5% moisture content) with low vapor transmission (< 3-5lbs per 1000 sq. ft./24 hours) before applying most types of membranes. This applies to both new and existing concrete substrates, although each may have its own set of moisture-related problems. For example, a 90-year-old poured-in-place partially buried concrete tank may face an entirely different set of circumstances from a newly constructed concrete slab with a steel tank mounted on it. Ultimately, the concrete needs to be dry prior to coating.

Topics: CIM 1000 Premix, CIM blog topic, CIM Documentation, drying concrete

Aggregates are commonly used in conjunction with liquid applied coatings to provide a combination of the following:

- Protection:

- Light colored aggregates lower deck temperature extending the life of liquid coatings

- Non-skid surfaces:

- For foot traffic

- For automotive and other traffic

- Exit areas for pond, containment, and other sloped surfaces

- Energy costs:

- Lighter colored aggregates will reflect solar energy, whereas dark-colored liquid coatings will absorb heat. Aggregate will reduce coating temperature by as much as 70 degrees on a hot summer day.

- Provides a rough surface in which to enhance the bond of other paints, coatings, and topcoats (asphalt, concrete, tile applications)

- For compliance with ANSI 118.10 IAPMO Approval for applications such as plaza and balcony decks.

Topics: CIM blog topic, Prerformance Enhancement

Waterproofing It Right The First Time...Mistakes Cost Valuable Time and Money

Tired of going back to repair waterproofing membranes which weren’t installed properly during the first application?

Time spent planning ahead of time and using proper application procedures can be some of the most important aspects of getting it done right the first time.

Costs associated with repair or “re-do” work can add up quickly. As an example, take a decorative fountain project.

Suppose the installer did not take the proper time and attention into preparing the surface for liner installation. The liner was installed on top of the poorly prepared surface.

Work continued with the installation of decorative stone on top of the liner. The result: the fountain looks great, but is it ready to be put into service? Probably not, because important preparation steps were ignored at the beginning.

Topics: CIM blog topic

Don’t Let Environmental Conditions Ruin Your Next Coating Project

Environmental conditions can wreak havoc throughout all phases of a coating application. To maximize the longevity and performance of the coating, we need to monitor environmental conditions, utilize proper testing equipment, and maintain daily field logbooks to stay on the path to coating success!

Environmental Effects on Coatings

Environmental conditions refer to the air and surface temperatures, relative humidity, dew point, and wind speed; each of these can negatively impact the coating if not properly monitored.

- Air and surface temperatures are the first conditions to check when assessing the potential for effects on the working and curing time of the coating as well as moisture formation on the substrate. It is equally important to verify that temperatures arein line with the manufacturer’s product recommendations.

Topics: CIM blog topic, CIM Documentation, Environmental Conditions

.png?width=650&height=278&name=CIM%20Chase%20logoK_301C%20(3).png)