Thermoplastic microspheres can be used in a wide variety of applications, but how do you know when...

What’s the Best Choice for Your Application? Thermoplastic vs. Glass Microspheres

There are several types of low-density hollow microspheres to consider when choosing a microsphere for your application. Thermoplastic, glass, ceramic and phenolic beads represent the main family of microspheres from which to choose.

There are several types of low-density hollow microspheres to consider when choosing a microsphere for your application. Thermoplastic, glass, ceramic and phenolic beads represent the main family of microspheres from which to choose.

The challenge is determining which type will be the best choice for your application. This will depend on your process and the goal of your product characteristics.

For the following comparison, we are going to focus on Dualite thermoplastic microspheres vs. hollow glass microspheres:

|

Characteristics |

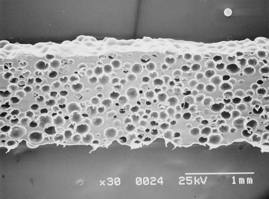

Dualite® Expanded Microspheres |

Glass Microspheres |

|

true density |

range from 0.03 g/cc to .135 g/cc |

range from 0.125 g/cc to 0.60 g/cc |

|

particle size |

range is from 25 microns to 150 microns |

range from 18 microns to 65 microns |

|

temperature resistance |

range from 250 F° to 350 F° |

maximum temperature 1112 F° |

|

pressure resistance |

range from 2000 psi to 2500 psi |

range from 250 psi to 28,000 psi |

|

shear resistance |

exceptionally shear resistant and sprayable |

rigid and friable and can break during mixing and spraying |

What’s Dualite’s ® Chemical Resistance?

|

|

Full Incompatibility |

Partial Incompatibility |

Stability |

|

Dualite® microspheres |

|

|

|

|

glass microspheres |

|

|

|

Based on the comparisons above, both Dualite® thermoplastic microspheres and glass microspheres have their strengths and weaknesses. If you need an ultra low-density material that is shear stable, flexible and sprayable, look no further than Dualite microspheres. On the other hand, if you need a high- pressure, chemical-resistant microsphere, choosing glass microspheres is the way to go.

If you would like a more in-depth consultation regarding your needs please contact us.