Cable manufacturers can be plagued by efficiency losses and production delays due to tape breaks....

Can SLICKTAPE® solve your tape forming issues?

Most cable manufacturers rely on forming tools to properly fold and align shielding tapes with the precision necessary to meet strict cable performance criteria. As you can imagine, running a foil tape across a metal forming tool creates friction that abrades both the tape and tooling itself. Any debris generated during the process, either from the tape or from its contact with the forming tool, eventually accumulates in the tooling causing unwanted cable defects and/or tape breaks due to space limitations. The typical practice in the wire and cable industry is to attempt to minimize this type of scuffing by directly lubricating either the tooling or the tape with oiling devices.

Some forming guide manufacturers offer antifriction inserts as a part of their basic designs. These inserts are made from materials such as PTFE film. Unfortunately, this form of lubrication is only a temporary solution because, due to wear, the film must be replaced frequently. Replacement frequency depends on the amount of friction and the length of the cable run. Long cable campaigns may even require planned line stops so that these inserts can be replaced. Further, a forming tool designed with a friction-reducing insert cannot be used without the insert because the gap has been adjusted to compensate for the PTFE thickness.

There are two basic methods for applying lubrication directly to a foil tape:

There are two basic methods for applying lubrication directly to a foil tape:

- One is the use of mineral oil or other inexpensive hydraulic/machine oil added directly to the tape during processing. This is a simple process where a small reservoir supplies a gravity fed drip mechanism which keeps a cloth or other membrane moist with oil. The oil is transferred to the surface of a tape in-line as it is pulled through or across the membrane. These application devices are relatively simple to add to a cabling line; however, their drawback is that they are quite inconsistent in the amount of lubricant deposited on the tape. The amount of oil varies when the speed of the machine changes. The amount can also vary from operator to operator as they adjust or refill these very basic manual devices. It stands to reason that an inconsistent level of lubrication can result in inconsistent cable performance. If too little lubrication is applied, the process is not effective and scuffing continues to occur. If too much lubricant is added, it may interfere with other performance properties within a cable. This can be a significant issue with tapes that are designed to bond to other components within a cable.

- A second, more reliable alternative to these rudimentary oiling devices is the use of an innovative lubricate coating developed by Chase. This unique coating is applied to the foil side of the

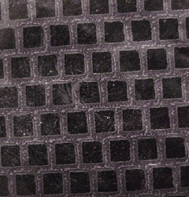

shielding tape and is designed to deliver a precisely controlled level of lubrication between the tape and the forming tool without compromising any of the other performance requirements. This dry coating, trademarked as SLICKTAPE®, provides an industry proven alternative to maximize cabling process speeds while minimizing friction and buildup of debris in the forming area. SLICKTAPE® eliminates the inconsistencies of direct oiling methods through both its unique chemistry and through an innovative coating pattern. This pattern ensures the optimum amount of lubrication is applied but also maintains a pathway for metal to metal continuity to the foil surface. In fact, the tape remains dry until there is enough friction to release the lubricant from the proprietary coating. Only then, a thin film of oil is present and coats the surrounding tape surface and the folding tool itself. Because the lubricant is built into the tape construction, operator intervention is not required to ensure a consistent application. As a result, manual oilers can be eliminated, the work area remains clean and cable defects are minimized. If tape lubrication is necessary, SLICKTAPE® will provide you with the most trusted and least intrusive method to maximize cable efficiencies.

shielding tape and is designed to deliver a precisely controlled level of lubrication between the tape and the forming tool without compromising any of the other performance requirements. This dry coating, trademarked as SLICKTAPE®, provides an industry proven alternative to maximize cabling process speeds while minimizing friction and buildup of debris in the forming area. SLICKTAPE® eliminates the inconsistencies of direct oiling methods through both its unique chemistry and through an innovative coating pattern. This pattern ensures the optimum amount of lubrication is applied but also maintains a pathway for metal to metal continuity to the foil surface. In fact, the tape remains dry until there is enough friction to release the lubricant from the proprietary coating. Only then, a thin film of oil is present and coats the surrounding tape surface and the folding tool itself. Because the lubricant is built into the tape construction, operator intervention is not required to ensure a consistent application. As a result, manual oilers can be eliminated, the work area remains clean and cable defects are minimized. If tape lubrication is necessary, SLICKTAPE® will provide you with the most trusted and least intrusive method to maximize cable efficiencies.

If you believe SLICKTAPE® can benefit your cabling process, ask for more information or ask for a sample by using the following link: http://info.chasecorp.com/wire-and-cable or by calling (781) 332-0700 and asking to speak to someone in Customer Service.