Understanding cathodic disbondment, its causes, and its importance is an excellent first step in ensuring long service life and optimal performance on…

The Snowballing Damage of Cathodic Disbondment on Pipelines

Topics: Cathodic Protection

How Cathodic Protection Systems Prevent Pipeline Corrosion

Corrosion or rust (Ferric Oxide) is not an aesthetically pleasing sight. On its surface, its red-brown coloration gives the appearance of a neglected…

Topics: Cathodic Protection

How to Fill Pipeline Casings - Process Guide and On-Site Checklist

Topics: Royston, Pipe Protection, Casing fill, pipeline casing

Calculate and Fill Pipeline Casings with the Right Volume of Filler

Pipeline casings, also known as pipeline sleeves or conduits, are protective structures used to encase pipelines that pass through various obstacles or…

Topics: Royston, Casing fill, pipeline casing

Protecting Pipelines with Filled Pipeline Casings

Pipeline casings, also known as pipeline sleeves or conduits, are protective structures used to encase pipelines that pass through various obstacles or…

Topics: Pipeline coatings, Corrosion protection, pipeline casing

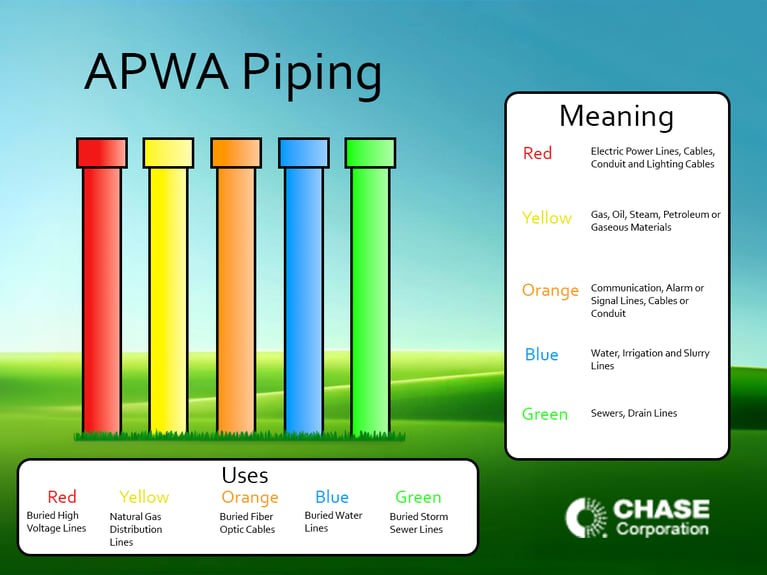

Pipe and Pipeline Color Code Standards Explained

Working in the vicinity of pipes or directly on pipelines can be dangerous. For the safety of all involved, safety and regulatory organizations have…

Topics: Pipeline coatings, Pipeline

Surface Preparation and Application Standards for High-Temperature Coatings

It doesn't matter what kind of pipe you're working with, proper surface preparation is one of the most important factors in saving pipelines from the…

Topics: Pipeline coatings, high-temperature, pipeline tape, SSPC, NACE

Protect Against Pipeline Corrosion in High-Temperature Environments

High-temperature corrosion protection coatings are developed to meet the harsh environmental conditions common to pipelines and the demanding requirements…

Topics: Pipeline coatings, high-temperature, pipeline tape

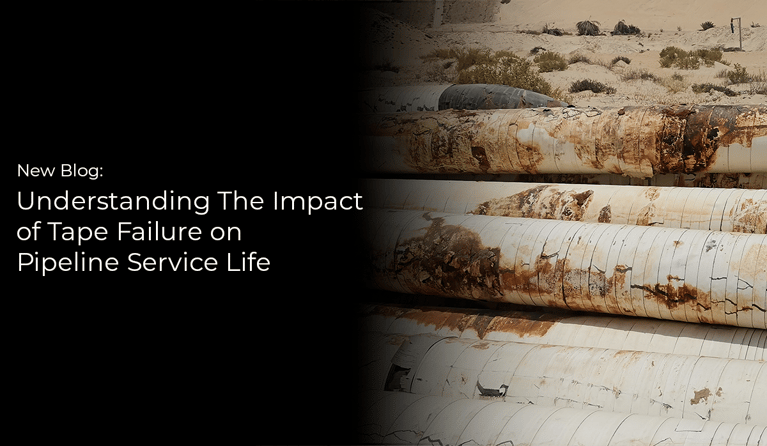

Understanding the Impact of Tape Failure on Pipeline Service Life

This Summer, the Chase Pipeline team was asked to come out and assist in recoating a non-potable water pipeline in Eastern Saudi Arabia. The pipe was…

Topics: Pipeline coatings, Tapecoat, Tape Failure, Service Life

Protect Thermite Welds On A Cathodic Protection System

To understand the importance of protecting thermite welds, we must first identify their location in a cathodic protection system. Cathodic protection can…

Topics: Corrosion protection, Pipeline, Thermite Welds, Cathodic Protection