Expansion joints are vital to the life of a bridge itself and must be correctly installed and...

Improving Expansion Joint Installation with Terrastrips

Concrete is a unique construction material. In its initial state, concrete is viscous, and it can be shaped into many different forms. Once cured, concrete becomes a hard and stiff material. Surprisingly, it is porous as well; despite the appearance of being rock solid, it tends to expand and contract.

When adjacent slabs of concrete are poured or formed, there should be enough space between the two slabs to allow for those slabs to move due to thermal expansion and contraction. In addition, changing temperatures cause pressure that can build up inside concrete, resulting in cracking. The method to relieve the cracking is to insert expansion or control joints. This will permit the concrete slabs to move freely and independently of each other.

Related Article: Expansion Joints on Bridge Decks

Expansion Joint Materials

There are a number of materials that may be used as expansion joints. Among the most effective, especially when the expansion joints are exposed to ultraviolet (UV) light, are closed-cell foam seals with HALS (Hindered Amine Light stabilizers). Exterior UV-exposed concrete slabs should have expansion or control joints to control cracking.

A potential issue in exterior concrete exposures is the ability of the expansion joint material to withstand not only wet-dry thermal cycling but also exposure to ultraviolet sunlight. This would be the case with steel bridge decks where the expansion joints are also exposed to cycling and ultraviolet light. Concrete construction slabs for industrial, commercial, or architectural applications, can by design have a depth greater than one foot. Depending on the material used and that material’s ability to withstand ultraviolet exposure, expansion joints can be expensive.

Terrastrips and Closed-Cell Expansion Joints

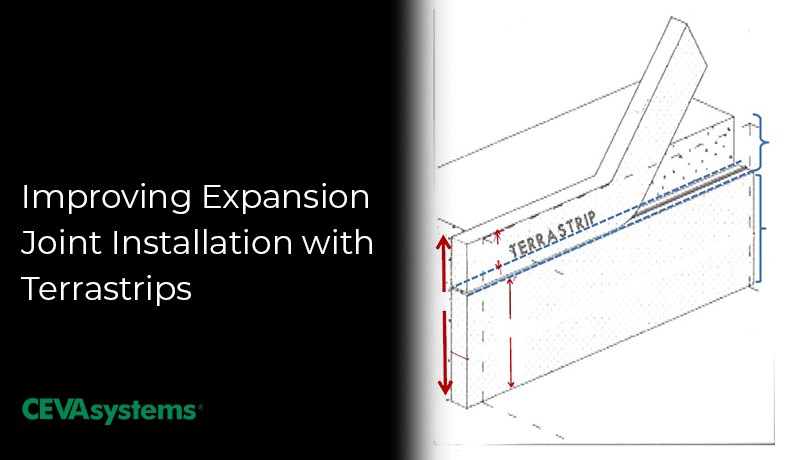

So how do you balance finding a material that fills the gap between concrete slabs while offering sufficient exposure resistance? We recommend considering a Terrastrip system. Ceva Terrastrip is a cost-effective joint filler used as a cast-in-place form with a top strip that pulls out after the poured-in-place concrete has been set. As an inert, preformed closed-cell foam, the Terrastrip can be custom cut to your requirements for depth of material, depth of tear-out, and width of material.

After removing the tear-away strip, which is sized according to specifications on plans, a control joint or expansion joint can be installed with a Ceva System using an ultraviolet-resistant closed-cell foam seal with HALS. For interior applications, the same process would apply, except an ultraviolet-resistant material would not be required. For instance, in an interior expansion joint where a chemical-resistant joint filler is required.

Chase Corporation offers a variety of expansion joint solutions. If you have any questions or require information for your next project, please visit the Chase website at www.chasecorp.com/Expansion.