This blog post outlines the techniques required for the removal of HumiSeal UV cure conformal...

Reducing Masking and Rework Costs with Better Conformal Coating Selection and Application

In electronics manufacturing, conformal coating protects printed circuit boards (PCBs) from moisture, dust, corrosive gases, and condensation. Yet while the benefits are well understood, the hidden costs tied to masking and rework can significantly erode a manufacturer’s bottom line.

Masking connectors, sockets, and keep-out zones is time-consuming, and reworking boards with coating defects consumes material, labor, and production capacity. For many assemblers, masking and rework represent the single largest share of conformal coating process cost. The good news: with better coating material selection and application process optimization, these costs can be dramatically reduced—without sacrificing protection or reliability.

→ Estimate process savings with the Conformal Coating Calculator

Why masking and rework costs add up

Masking is one of the most labor-intensive steps in PCB assembly lines where conformal coating is used. Complex layouts with multiple keep-out areas require operators or automation to carefully protect components from coating exposure. A single error in masking can lead to coating creep, bridging, or miscoverage—forcing rework.

Rework itself introduces additional cost layers:

- Labor: Coating removal and re-application require skilled technicians.

- Material waste: Each cycle consumes more coating and masking materials.

- Throughput loss: Every board that requires rework slows the line and delays shipments.

- Quality risk: Multiple rework cycles increase the chance of defects or reduced reliability.

Studies in electronics manufacturing indicate that masking and rework can contribute a significant portion—often 20–40%—of total conformal coating process cost. Reducing these costs is one of the highest-ROI opportunities for process improvement.

Factors that drive masking complexity

Several variables influence how much masking and rework effort is needed:

- PCB design: Dense component layouts and tall components create shadowing and awkward geometries. The more intricate the board, the greater the masking requirement.

- Coating chemistry: Different coatings behave differently during application. High-wetting materials may creep under masking tapes or around sharp edges, while low-viscosity coatings can wick into connectors.

- Application method: Automated selective coating systems reduce labor compared to manual methods, but performance depends heavily on how the chemistry behaves in the spray pattern.

- Cure profile: Some coatings cure rapidly and are easier to control, while others may flow or sag before cure, creating coverage defects.

Understanding these drivers is essential when evaluating opportunities to minimize masking and rework costs.

Choosing the right conformal coating to reduce masking needs

Material selection plays a pivotal role in controlling coating behavior during application. Traditional acrylics and urethanes provide excellent protection but can present challenges with overspray, wetting, and spattering during automated processes. These behaviors increase masking effort and raise the likelihood of rework.

Newer materials—such as HumiSeal® 1B59 SEC—are engineered to address these challenges and support modern selective coating equipment and systems. In particular:

- Reduced wetting and creep: Formulated to stay where applied, reducing the risk of encroachment into keep-out zones.

- Minimal spattering: Stable droplet formation during spray helps ensure clean, sharpedge coverage and less contamination of masked areas.

- Controlled overspray: Narrow spray boundaries mean less unintentional coating deposition, reducing both masking effort and post-process clean-up.

- Consistent coverage: Predictable flow patterns help achieve the desired protection with fewer process adjustments.

Learn more: Discover the Global Leader in Conformal Coating Technology

These attributes translate into lower masking requirements and reduced rework rates. Rather than relying on heavy masking labor or multiple rework passes, assemblers can depend on the coating to behave predictably in automated systems—improving throughput and quality.

Cost-benefit snapshot

Switching to newer coating chemistries or upgrading selective conformal coating equipment and systems involves upfront investment, but long-term savings are substantial:

- Reduced masking labor → redeploy operators to higher-value tasks.

- Lower rework rates → less scrap and fewer repair cycles reduce the overall cost of quality.

- Higher throughput → faster processing with fewer interruptions supports higher output.

- Improved reliability → fewer defects translate into stronger field performance and fewer warranty claims.

For many operations, the payback period for adopting a new coating or application process can be measured in months, not years.

Conclusion & key takeaways

Masking and rework costs are often underestimated when evaluating conformal coating processes. Yet they can represent up to 40% of total cost—and they’re highly controllable. By choosing coatings engineered for automation—such as HumiSeal 1B59 SEC—and pairing them with optimized selective application processes, manufacturers can significantly reduce both masking labor and rework rates.

The result is not only lower production cost but also improved throughput, higher quality, and stronger long-term reliability of electronic assemblies. For organizations seeking competitive advantage in high-reliability markets like automotive, industrial, aerospace, and medical devices, optimizing conformal coating is one of the most effective paths to savings and performance gains.

|

|

|

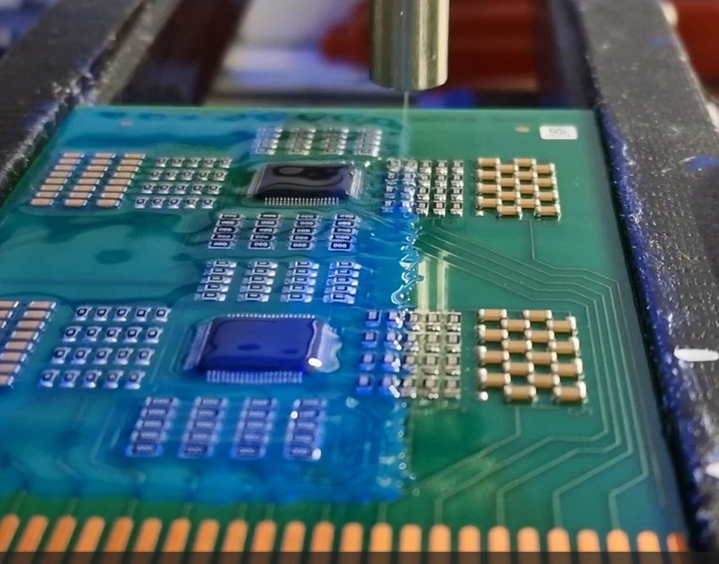

Figure 1 - Clean, splash-free coating deposition by automated spray with HumiSeal® 1B59 SEC |

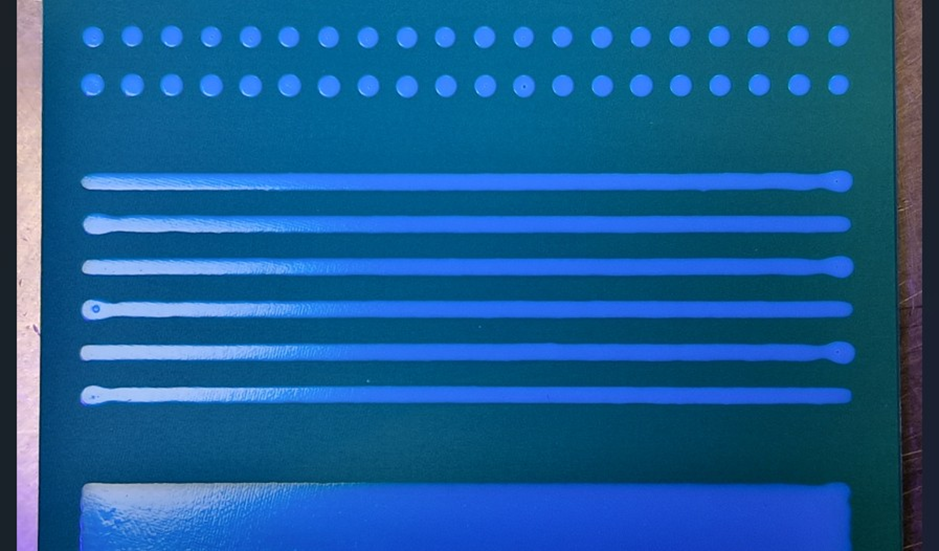

Figure 2 - Splash-free, clean line definition by jetting nozzle with HumiSeal 1B59 SEC |

FAQ's

Q1. How much can masking and rework add to conformal coating cost?

Often 20–40% of total process cost, depending on design, chemistry, and application method.

Q2. How do we avoid masking in our electronics coating process?

Use coatings formulated for selective application with controlled overspray and minimal creep, and pair them with tuned spray paths and fixturing.

Q3. How do we avoid overspray or splatter of conformal coatings during application? Match coating chemistry to the valve type and program for narrow spray boundaries; validate atomization, edge quality, and droplet control.

Q4. How can we apply conformal coating only to part of a PCB?

Selective coating with programmed keep-out zones and appropriate valves (spray, film, or needle) targets only required areas.

Q5. What is selective coating?

A controlled, automated process that deposits conformal coating only where specified using programmed paths and valves.

Q6. What’s the difference between overspray and creep?

Overspray is unintended deposition outside the target area; creep is wetting/flow into keepout zones after deposition.

Q7. What is sharp-edge coverage in conformal coating?

The ability of a coating to form clean, well-defined edges on components and board features, minimizing overspray and creep into keep-out zones.

Q8. Do coatings exist that reduce masking needs?

Yes. Materials engineered for automation can limit overspray, spatter, and creep—reducing masking and rework.

Q9. What do people mean by “lacquer” on PCBs?

It’s a common informal term for conformal coatings used for electronics protection.