Consider the following two questions:

- Is your company a supplier of electronics or PCBs to the automotive industry?

- Are you or your team responsible for assuring a steady supply of quality products such as conformal coatings and encapsulants?

If so, we would respectfully ask you to consider adding IATF 16949 certification to your list of requirements for your key suppliers.

Many coatings suppliers continue to focus on minimizing costs and maximizing profits. As a result, most have not taken the time or expense to get themselves IATF certified. In our conversations with major OEMs, we can assure you that the IATF certification of your suppliers can be of great value and help you sleep better at night.

Related Article: Understanding IPC-CC-830B Qualification Standards

Read More

Topics:

Conformal Coatings,

Electric Vehicle

This blog post outlines the techniques required for the removal of HumiSeal UV cure conformal coating. The products covered in this article are:

- UV40, UV40-250

- UV50LV

- UV500, UV500LV

Read More

Topics:

Conformal Coatings,

Humiseal,

Micro Abrasion,

conformal coating removal

Before we look at conformal coating in the 21st Century, it is worth looking at how our industry has changed since the 20th Century and the effect these changes have had on reliability.

30 years ago, we had:

- Through-hole PCAs with axial components and wide conductor spacing (see fig. 1)

- Round axial components that were easy to conformably coat

- Wide conductor spacing (causing a few problems with dendritic growth)

- Leaded solder

- The widely adopted practice of cleaning before conformal coating

Fig. 1

Now move forward 30 years. In that time, surface mount components have been developed that are predominantly square with sharp edges, conductor spacing has been reduced, and packing densities have increased to levels never dreamt of in the past (see fig. 2).

Read More

Topics:

Conformal Coatings,

Sharp Edge

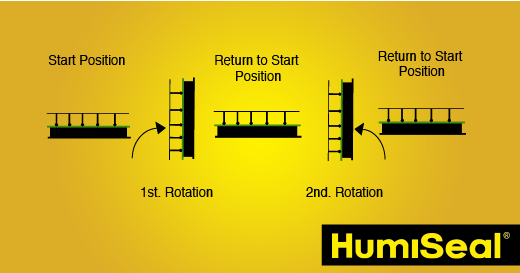

When conventional coating methods such as hand spray, total dipping or robotic selective coating don’t provide the protection required, there is always selective dip coating.

What is selective dip conformal coating?

Selective dip coating is a process whereby the substrate rather than globally immerised in the coating, is discreetly coated in desired locales. The technique in one form or another, has been around for over 25 years and is used with both classic solvent-based coatings and 100% UV cure conformal coatings.

Read More

Topics:

Conformal Coatings,

Humiseal,

Selective Dip Coating,

Electronic Protection

Counterfeit conformal coatings have infiltrated the electronics industry, posing a significant threat to device reliability. These counterfeit coatings may look like genuine products, but they lack the quality and protective properties required for electronic applications. Here are some reasons why counterfeit conformal coatings are causing failures:

Read More

Topics:

Conformal Coatings,

counterfeit

Conformal coatings have a long and storied history with printed circuit boards. A good conformal coating protects PCB components from moisture, corrosion, contaminants, and additional PCB threats like vibration and thermal shock. Coatings are a complicated science, and there isn’t one best coating or application method for every job. These choices are dependent on the design, use case, and assembly of the PCB. For instance, manual brushing PCB coating material is a slow, tedious process; but for small batch applications, it’s quite cost-effective.

Regardless of the chosen method, there are fundamental application errors that can occur, leading to defects forming in the coating which ultimately limit the functional service life of the PCB.

Read More

Topics:

Conformal Coatings,

Protection for PCB,

Conformal Coating Troubleshooting

Conformal coating technology is on a continuous path of improvement, and we're excited to say the latest step on that path just happened. UV550 is the most recent innovation from HumiSeal, continuing the trend of industry-defining capabilities in the conformal coating space. This is to be expected from the original inventors of conformal coating material. But what sets UV550 apart from the rest?

Let's discuss how the ever-changing requirements of the automotive and white market space fueled the thresholds this uv-curable material attains, especially with regard to its durability under the most extreme thermal and mechanical cycling conditions.

Read More

Topics:

UV Curable (Type AR/UR),

Conformal Coatings,

UV Curing,

UV550

We at HumiSeal are no strangers to conformal coatings; and if you’re reading our blogs, it’s likely you’re familiar with these coatings as well. The word “conformal” is descriptive of the function of the coatings which are expected to spread and conform evenly across all surfaces that are to be protected. This uniform and even distribution is necessary to protect delicate electronic components from things such as humidity, water, vibrations, and thermal damage (to name a few).

Read More

Topics:

Conformal Coatings,

Conformal Coating Troubleshooting,

Sharp Edge

Manual brushing is just one of many methods commonly used for applying conformal coating materials to PCBs and other components. It is a hand-applied method that requires little investment into automation or equipment. With practice, it can be one of the simplest methods available, especially for small-batch production or isolated applications.

Read More

Topics:

Conformal Coatings,

conformal coating application,

Manual Brush

Modern hydrogen fuel cell technologies require ever more sophisticated and reliable electronic control systems to assure both safety and longevity. Hydrogen fuel cells are gaining in popularity in critical industries including automotive, aerospace, ocean transportation, military, and power microgrid systems among others. Protection of printed circuit boards and their components from physical, chemical, and thermal damage is essential to produce robust and reliable fuel cell systems for demanding applications.

Read More

Topics:

UV Curable (Type AR/UR),

Conformal Coatings,

Humiseal Blog,

Conformal coating benefits,

UV Curing,

microgrids,

renewable energy