One of the most basic and common questions we at HumiSeal® are asked by both existing and potential...

The Next Stage of Total PCB Protection: Sharp Edge Conformal Coatings

We at HumiSeal are no strangers to conformal coatings; and if you’re reading our blogs, it’s likely you’re familiar with these coatings as well. The word “conformal” is descriptive of the function of the coatings which are expected to spread and conform evenly across all surfaces that are to be protected. This uniform and even distribution is necessary to protect delicate electronic components from things such as humidity, water, vibrations, and thermal damage (to name a few).

If your business relies on the continued performance of PCBs and their intricate parts, there’s a question you must ask yourself this very moment. How “conforming” is my conformal coating? Often, the honest answer is less than anyone would like as all conformal coatings have a difficult problem to resolve, and this issue comes during application.

The Problem with Conformal Coating Application

Modern PCBs are smaller and more densely populated with sensitive components than ever before, especially in demanding industries such as automotive and aerospace. Conventional application methods generally involve spraying or dipping to spread conformal coatings as evenly as they can manage, but the process is not without limitations.

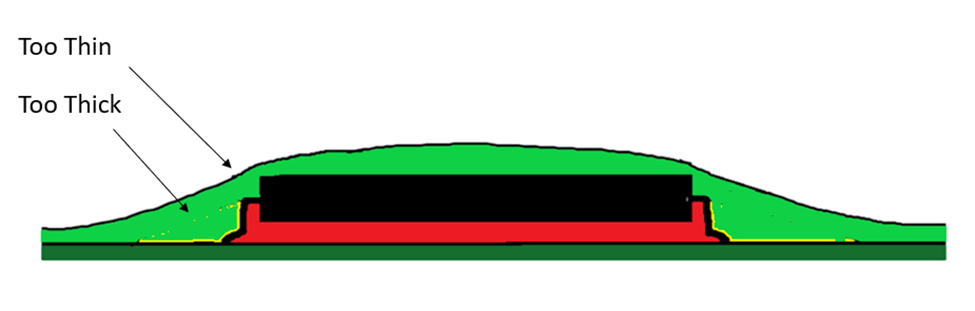

Current spray and manual brushing applications are limited in their ability to apply even thickness across an uneven surface by the processes of fluid dynamics and flow. As a result, below is a general depiction of a typical conformal coating distribution showing thin areas on and around vertical surfaces and thicker areas in areas prone to accumulation.

Spray and manual applications can only be applied so fine, even when handled by automation. As a result, this is a general depiction of conformal coating distribution.

So what’s the problem?

- When coatings are applied too thin, these areas do not get sufficient protection, leaving these corners at risk of corrosion and electrical failure.

- When coatings are applied too thick, the material risks cracking as too much coating fails to set properly, enhancing risk of cracks and exposing areas to various environmental conditions.

This problem is not new, and many industries fail to notice issues at all. This distribution pattern works, but can it work better?

Why Do Conformal Coatings Set Unevenly?

There are a few reasons for this, and it isn’t just because of sprayer heads. Let’s look at a few reasons why the spread isn’t perfectly uniform:

Viscosity on Uneven Surfaces

Lower solids and lower viscosity coatings will tend to flow off vertical surfaces more readily and solidify slower. This can lead to very even thickness on horizontal regions but an uneven spread on vertical sides. This is the result of natural fluid dynamics.

Carrier Solvent Volatility

Most conformal coatings are carried and dissolved in industrial solvents or water. The volatility of the carrier fluids can affect thickness and uniformity. Slower evaporating fluids will slow drying and solidification and lead to more flow off vertical components. Fast-evaporating solvents can help avoid excess flow but can lead to skinning or “orange peel” thickness variations on flat areas, as well as bubbles forming on the base of components where higher coating thickness is accumulated.

Surface Energy of the PCB and Components

Surface energy is a measurement of any surface or material’s ability to pull a liquid to form an even coating layer. Generally, higher values of surface energy result in better and more even wetting of the coating. The ideal situation for coating uniformity is high surface energy of the solid. It is common that plastic surfaces of PCB components will have low or inadequate surface energy due to mold release or plasticizing agents covering their surface. This often leads to poor wetting on the tops and corners of components.

Related Article: How to Make Sure Your Conformal Coating Actually Conforms

How do we solve these issues?

Introducing Sharp Edge Coatings from HumiSeal

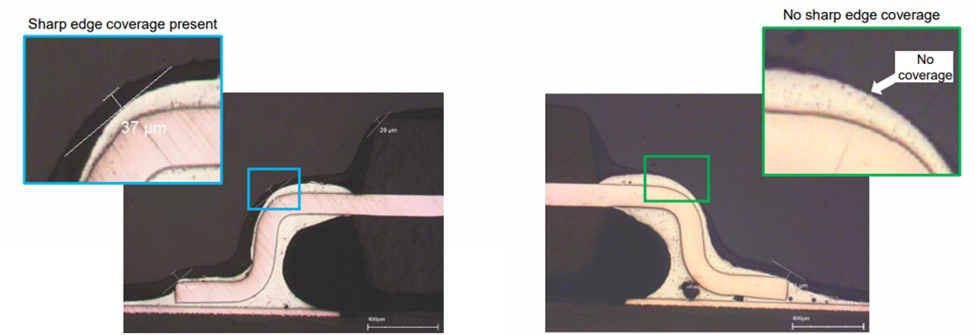

The scientists at HumiSeal have developed a new type of conformal coating material. This formulation is designed to adhere along the edges and sides of components better than ever before. This is the new Sharp Edge Coatings. While Sharp Edge Coatings are still early in their developmental life cycle, current testing has yielded significant improvements over traditional conformal coating applications.

As shown in the image below, HumiSeal Sharp Edge forms a tight bond during application. This mitigates the risk of cracking or otherwise insufficient coverage.

HumiSeal is working tirelessly to bring this solution to market. Sharp Edge Coatings are anticipated to eliminate common sources of conformal coating failures due to contemporary application practices. The goal, ultimately, is to offer a truly conforming solution that can be performed reliably and at scale (without tremendous investments into new machinery or similar overhead).

HumiSeal will be announcing more news in the future about Sharp Edge Coatings. The best way to stay informed is to subscribe to our mailing list and look out for future blog posts on the subject. As always, we are more than happy to answer any questions involving conformal coatings and their applications. Reach out and let’s schedule a time to talk!