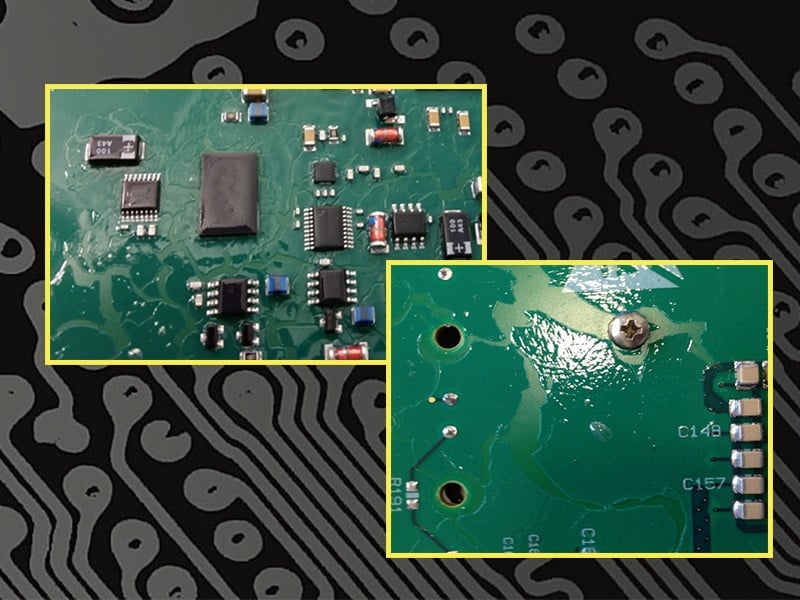

Have you ever seen your conformal coating separate or de-wet? Have you observed the conformal coating to flake off after cure? The key to your success is understanding the relationship between surface energy (of the substrate) and surface tension (of the conformal coating). There are some simple steps you can take to help ensure you possess a healthy balance of both.

Recent Posts

Simple Steps to Ensure Proper Wetting & Good Adhesion

Topics: Humiseal, Conformal Coating Process, proper wetting, troubleshooting, surface energy, conformal coating application

Simple Steps to Resolve Conformal Coating Wetting Problems

Does your conformal coating not wet properly? Do you struggle with craters, fish-eyes, or film separation? The culprit could be that the surface energy of your PCB is lower than the surface tension of the conformal coating. The above defects are discussed frequently with customers on our technical support line, and any time we receive a technical enquiry regarding poor wetting or loss of adhesion, we ask “what is the surface energy of your substrate?” In this blog, we will explain surface energy, surface tension, and how to quickly troubleshoot defects resulting from low surface energy.

Topics: conformal coating, conformal coating application, Conformal Coating Troubleshooting