Adoption of plug in -electric vehicles (EVs) has been slower than many expected, but there is little question the next few years will see adoption accelerate. Your hypersensitive dog will have to find new visitors to harass when your delivery drivers arrive without notice, driving to your door silently in all-electric commercial vans. Many of your favorite suppliers and stores have already ordered these vehicles. Game-changing battery and charging developments are eliminating range anxiety, and autonomous driving controls and safety innovations are in the final stages of building our trust.

Electric Vehicles: Polymers for Performance, Reliability, & Protection

Topics: Thermal Interface Materials, Vibration Suppression, Thermosink, Conformal coating benefits, EMI conductive gaskets, EV, Electric Vehicle

Protective Coatings and Polymers for Hydrogen Fuel Cell Electronics

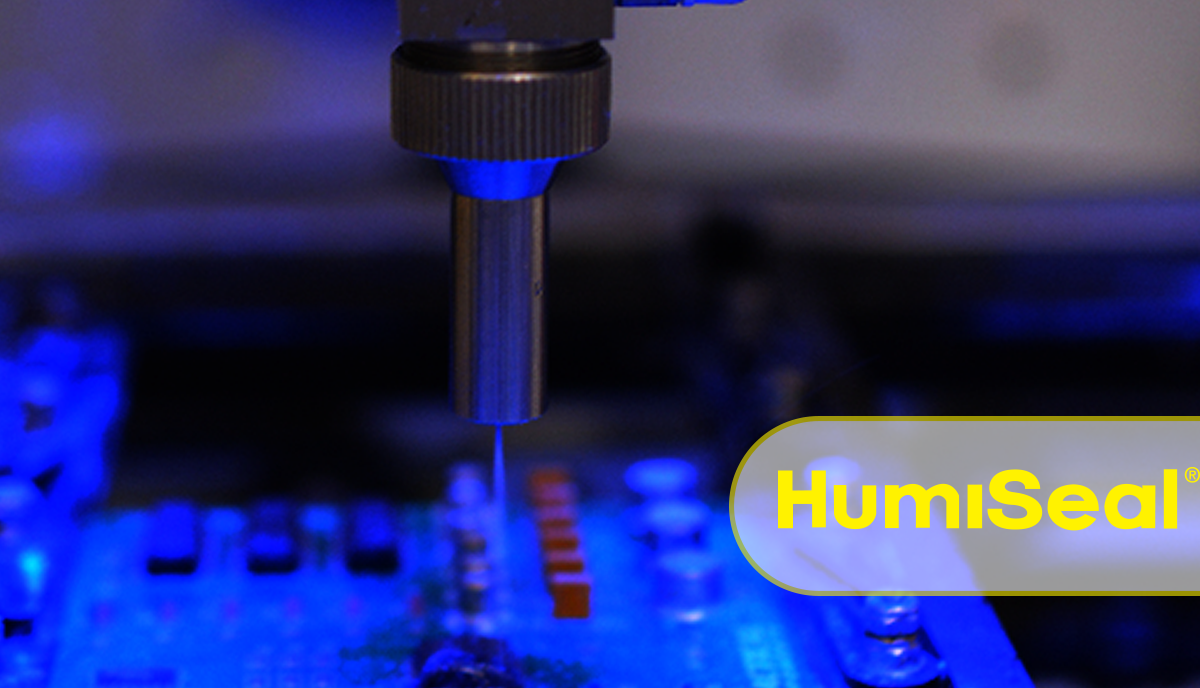

Modern hydrogen fuel cell technologies require ever more sophisticated and reliable electronic control systems to assure both safety and longevity. Hydrogen fuel cells are gaining in popularity in critical industries including automotive, aerospace, ocean transportation, military, and power microgrid systems among others. Protection of printed circuit boards and their components from physical, chemical, and thermal damage is essential to produce robust and reliable fuel cell systems for demanding applications.

Topics: UV Curable (Type AR/UR), Conformal Coatings, Humiseal Blog, Conformal coating benefits, UV Curing, microgrids, renewable energy

Understanding the Importance of the Moisture Vapor Transmission Rate of Conformal Coatings

A critical function of conformal coatings is to protect PCBs and electronics from damage caused by moisture and humidity. In this discussion, we will attempt to answer some of the more common questions we often hear regarding the level of protection you can expect from a conformal coating.

Are conformal coatings waterproof?

The above is probably the most common question and most misunderstood subject in the area of PCB protection

Topics: Environmental Conditions, Conformal Coating Process, Conformal coating benefits, waterproofing silicones, waterproofing

The Potential Cost of NOT Conformal Coating Your PCB

The PCB industry continues to evolve with ever increasing demands for efficiency and manufacturing cost reductions. From the design phase onward, suppliers and contract manufacturers are being asked by their OEM overlords for increased performance at lower and lower costs. An obvious potential source for cost reduction is the use of alternative cheaper raw materials or their elimination where possible. At some point in the discussion, it is sometimes asked, “Why don’t we just eliminate the conformal coating?” or "Are conformal coatings necessary".

Topics: conformal coating application, Conformal Coating Costs, Conformal coating benefits, Protection for PCB

Thinners for Conformal Coatings: The Basics of What, When, and How

You have completed your search for an ideal conformal coating chemistry, one that will provide your PCBs the protection and reliability demanded by your industry and customers. After all that work, you probably assume your job is finished. Our apologies for being the bearer of bad news: There is still work to be done. In this basic presentation and discussion, we will talk about the proper choice and implementation of thinners for your coating. In many cases, a mistake in thinner can harm or even completely negate the protective properties of your conformal coating when applied to your PCB.

Topics: thinners, Conformal coating benefits

Conformal Coating Quality + Reputation = Reliability for Your PCB

The electronics industry is exploding with the introduction of innumerable consumer devices designed with ever more complex functions and controls. These range from the relatively mundane such as controlling the temperature in your home to potentially life-saving including deploying airbags in your car or sensing hazardous road conditions. The demand for smarter and more complex electronics is becoming more important in everyday life.

Topics: Conformal Coating Process, conformal coating application, Conformal coating benefits

Easy Techniques to Abate Conformal Coating Wicking

Have you ever experienced uncontrolled conformal coating migration? Have you had to strip your recently coated boards because conformal coating wicked into non-desired keep out zones? Wicking is a phenomenon caused by a combination of low surface tension coating, which is usually characterized by low viscosity, coupled with strong capillary forces generated by low standoff gaps possessed by the SMT process. Wicking into connectors; onto grounding hole; or under sensitive components will create defects that will have to be reworked, as it may cause reliability concerns with the finished product, which we will describe in detail. There are ways to either reduce and/or eliminate wicking issues through decisions made during preparation, application, and conformal coating selection.

Topics: silicone conformal coating, Electronic Protection, Conformal coating benefits, Wicking