Conformal coating technology is on a continuous path of improvement, and we're excited to say the latest step on that path just happened. UV550 is the most recent innovation from HumiSeal, continuing the trend of industry-defining capabilities in the conformal coating space. This is to be expected from the original inventors of conformal coating material. But what sets UV550 apart from the rest?

Let's discuss how the ever-changing requirements of the automotive and white market space fueled the thresholds this uv-curable material attains, especially with regard to its durability under the most extreme thermal and mechanical cycling conditions.

Read More

Topics:

UV Curable (Type AR/UR),

Conformal Coatings,

UV Curing,

UV550

HumiSeal development specialists have been designing high-performance, UV-curable conformal coatings for approximately three decades. Compared to legacy solvent-borne and silicone technologies, UV- curable coatings provide some unique properties that can be of great value such as-

- Nearly instantaneous, consistent curing

- Superb moisture and environmental protection

- Little or no VOC content

These coatings also lend themselves well to high-speed and high-volume applications due to manufacturing advantages such as-

- Minimal WIP due to immediate cure capability

- Low material cost due to 100% solids chemistry

- Smaller manufacturing footprint due to much smaller curing equipment

Read More

Topics:

UV Curable (Type AR/UR),

conformal coating,

conformal coating application,

UV Curing

We recently published a blog outlining radiometer configuration and usage. Give it a read if you missed it! Since you’re now an expert at operating your radiometer, this blog will look at the steps needed to optimize your UV or LED oven.

This process is practically as simple as increasing and decreasing the UV or LED cure system’s conveyor speed to affect the dose. You must also consider increasing and decreasing the distance between the cure system’s lights and the radiometer to achieve at least the minimum irradiance required per the coating, adhesive or GELS technical data sheet.

One further note regarding LED cure systems is to ensure you’re using a light source that not only has the correct power (Watts), but also emits UV energy in the correct wavelength.

How to Calibrate a UV or LED Curing Oven

Read More

Topics:

UV Curing,

LED curable conformal coating,

Radiometer

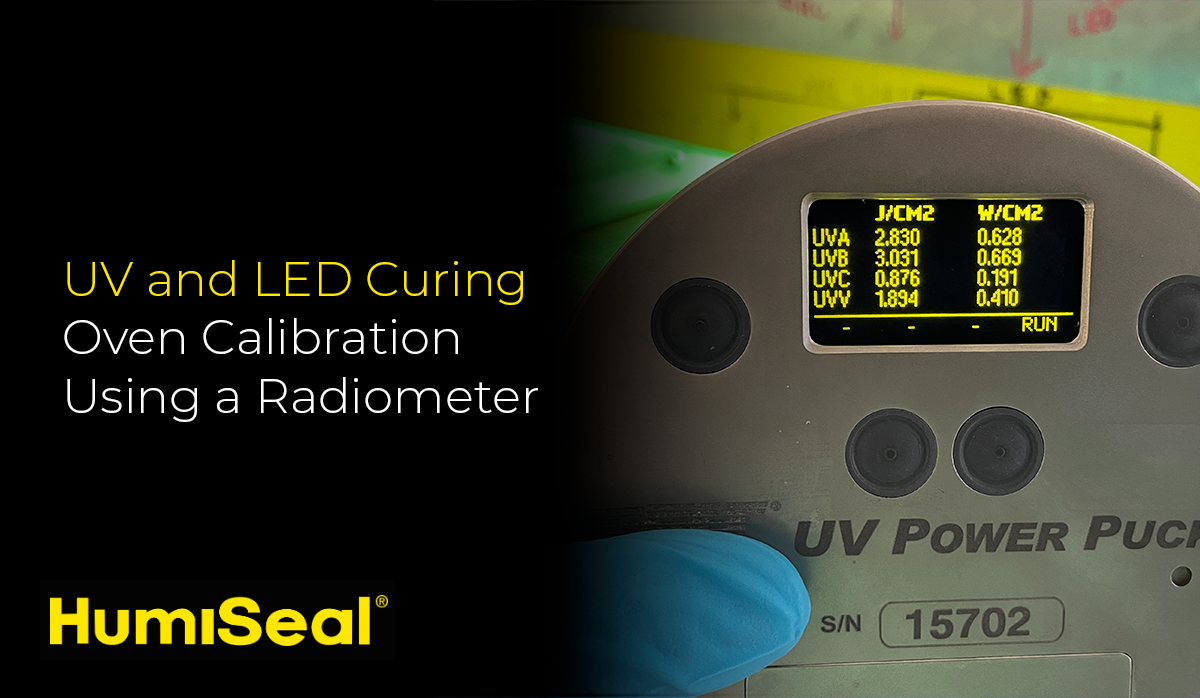

It's 2023; the electronics industry is embracing UV-curable coatings. There are many valid reasons for this, from the desire to reduce/eliminate VOCs, difficulty navigating ever-changing and complex environmental regulations, increasing energy and labor costs as well as the sheer volumes modern assembly lines must increasingly meet.

Read More

Topics:

UV Curing,

LED curable conformal coating,

Radiometer,

PowerPuck

The transition to LED curable conformal coatings is beginning to build momentum, beginning as a slow evolution and developing into a revolution of sorts. The driving forces behind this include:

- Improved processing equipment designs and availability

- Aging or outdated application equipment replacements

- Increasing range of LED curables commercially available or in development

- Rising labor, equipment, and energy costs

If you and your organization are faced with aging equipment and higher costs, there isn't a better time to consider the potential advantages of LED curable conformal coatings!

Read More

Topics:

conformal coating,

Protection for PCB,

UV Curing,

LED curable conformal coating

UV curable conformal coatings have attained widespread use in applications requiring fast through-put times, such as automotive, white goods, and industrial control manufacturing. In addition to speed of cure, UV curable conformal coatings provide the advantage of high physical protection and chemical resistance for electronic systems. Traditionally the UV curing of coatings is an energy intensive process. One that uses high-power mercury discharge lamps, which as a result of use produce considerable amounts of heat and ozone. The recent introduction of new, high-output LED UVA light units allows for the successful cure of conformal coatings by using between 365nm and 395nm wavelength of UVA light, effectively curing with minimal heat and no ozone generation.

Read More

Topics:

UV Curable (Type AR/UR),

Conformal Coating Process,

conformal coating application,

UV Curing,

UV light,

UVA

Modern hydrogen fuel cell technologies require ever more sophisticated and reliable electronic control systems to assure both safety and longevity. Hydrogen fuel cells are gaining in popularity in critical industries including automotive, aerospace, ocean transportation, military, and power microgrid systems among others. Protection of printed circuit boards and their components from physical, chemical, and thermal damage is essential to produce robust and reliable fuel cell systems for demanding applications.

Read More

Topics:

UV Curable (Type AR/UR),

Conformal Coatings,

Humiseal Blog,

Conformal coating benefits,

UV Curing,

microgrids,

renewable energy