There are several types of microspheres available, each with its own advantages and disadvantages...

Pumping vs Dumping Microspheres: What's Best for You

Dualite Polymeric Microspheres are ultra-lightweight fillers used in a variety of applications, most notably construction products, composites, coatings, and automotive sealers.

Due to their very low densities and small sizes, they can easily become airborne during the production process. Unfortunately, uncoated expanded polymeric microspheres are considered a dust explosion hazard and require special handling and grounding of the equipment. Fortunately, Dualite Microspheres are coated, rendering them a non- dust explosion material.

You can check out our list of non-dust explosion microspheres on our website.

Dumping vs pumping is a relatively straightforward debate, and the best solution is unique for each operation. Let’s look at the differences between the two and understand what you need to make the right decision.

Dumping Microspheres

Microsphere dumping is an incredibly straightforward process, and that is both a benefit and a detriment. Dumping is about as simple as it sounds: tip the container and watch the microspheres fall into the main solution, not unlike adding flour to a mixing bowl.

The Main Benefits of Dumping:

- It’s fast

- It’s easy

- It requires no special equipment

The main flaw: It kicks up microsphere dust into the air, risking a dust explosion.

This isn’t a problem for coated microspheres like Dualite, but this is definitely an important factor to consider before dumping. Additionally, dumping microspheres sacrifices control, meaning the process of dumping kicks up a portion of microspheres into the air--which are ultimately lost. This waste can be considered a needless overhead expense.

Even when a volatile explosion is not the biggest concern, dumping is still far from a perfect solution.

Pumping Microspheres

Pumping microspheres is a slightly more complex process. It requires the use of a specialized tool called an air diaphragm pump. Microspheres have an interesting property where they flow like a liquid under high pressure. The pump enables microspheres to flow into a solution in much the same way as a standard gas pump.

Main Benefits of Pumping:

- It’s highly controlled

- It’s safer than dumping

- It’s far more efficient.

The main issue with pumping comes from the specialized equipment required to pump. The machine itself isn’t too complicated to use, but any machine is more of a challenge than no machine. However, if the primary goal of your microsphere application is to limit product loss and dusting, there’s no better solution than pumping.

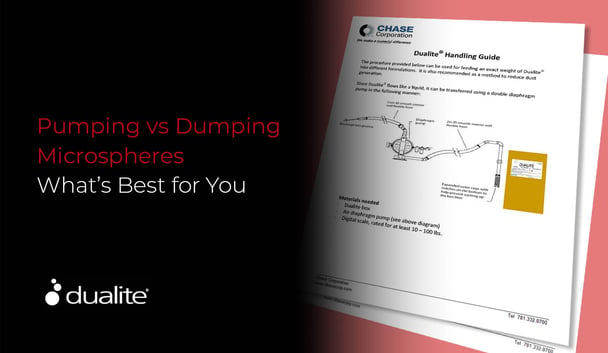

Luckily, using an air diaphragm pump isn’t too difficult. In fact, we have an easy-to-read guide that will walk you through the entire process. You can find the link to the guide here:

However you intend to use microspheres, Dualite has you covered. Once you come to a decision on pumping vs dumping, you may want to decide between expanded and unexpanded microspheres (we have you covered there too). If you have any questions about the topics covered here, reach out! We’d love to help you with any microsphere-related questions you may have.