There are several types of low-density hollow microspheres to consider when choosing a microsphere...

Understand the Thermal Compatibility of Polymeric Microspheres

By understanding the Thermal Compatibility of Polymeric Microspheres, it will help guide you in testing them in your formulas.

By understanding the Thermal Compatibility of Polymeric Microspheres, it will help guide you in testing them in your formulas.

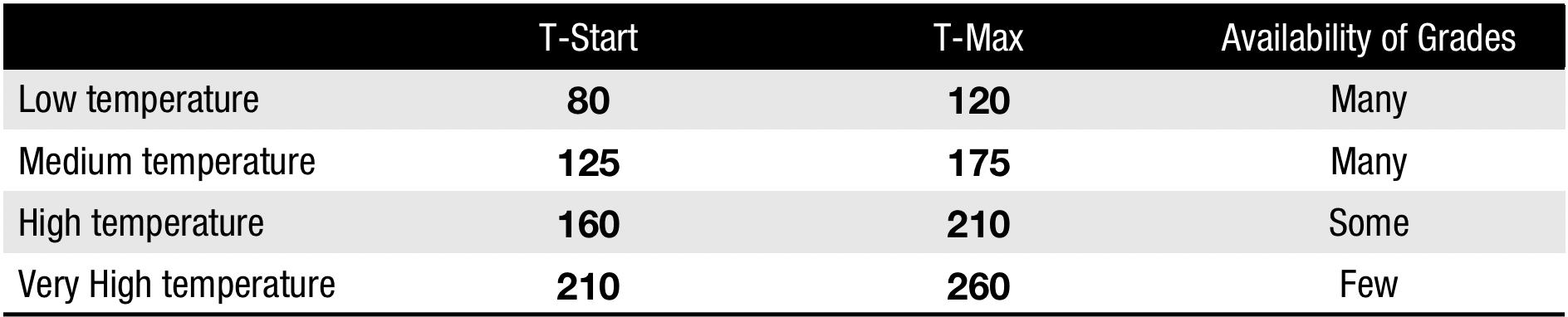

Microsphere grades are available in a wide range of operating or expansion temperatures. The ranges are defined by T start which is the lowest temperature at which the microsphere shells begin to soften to allow expansion, and Tmax, which is the temperature at which the maximum expansion is achieved for very short exposure times (i.e. 1 – 3 minutes). Short exposures at temperatures above T max or long exposures at temperatures below Tmax but above T start will cause rupturing of the microspheres.

Related Article: Get the Right Mix of Microspheres & Solvents in Your Formula

Microsphere grades can be grouped into several classes for ease of discussion. In the table below, single point temperatures have been selected for the T start and Tmax ranges just to give a rough idea of the temperatures involved; they are not exact numbers by any means. A hypothetical example illustrating the use of these numbers is included in the Appendix.

Fig. 1. Microsphere expansion temperatures / softening temperatures (deg C)

The table in Fig. 2 shows the melting point of selected thermoplastic materials. For a microsphere grade and a thermoplastic to be thermally compatible, the melting point of the plastic must be below the T start of the microsphere so that they can be initially mixed without causing expansion. Since PET, PTFE, PEN, and polyimide all have melting points above the T start of even the highest temperature microsphere, they cannot be used together. On the other hand, EVA, PE, PP, and some PVC materials have melting points below the T start of some medium temperature microspheres and all high temperature grades, so they are compatible.

- EVA – ethylene vinyl acetate m.p. ~100 C for lower levels of VA; At VA`30 – 40% m.p. ~50 – 60 C

- PE – polyethylene p. 115 – 135 C

- PP – polypropylene p. 130 – 170 C

- PVC – polyvinyl chloride p. 100 – 260; Tg = 82 C

- PTFE – Teflon p. 327 C

- PET – polyethylene terephthalate – polyester m.p. 260 C, film shrinkage at 150 C

- PEN – polyethylene naphthalate; and polyamides – more heat stable than PET

Fig. 2. Melting temperatures of selected thermoplastic materials

Related Article: 8 Reasons Why You Should Consider Polymeric Microspheres

Testing is a critical phase, so mixing the right combination will significantly increase your chances of success.

If you would like further information or would like to speak to someone regarding your application, please contact Chase Corporation.