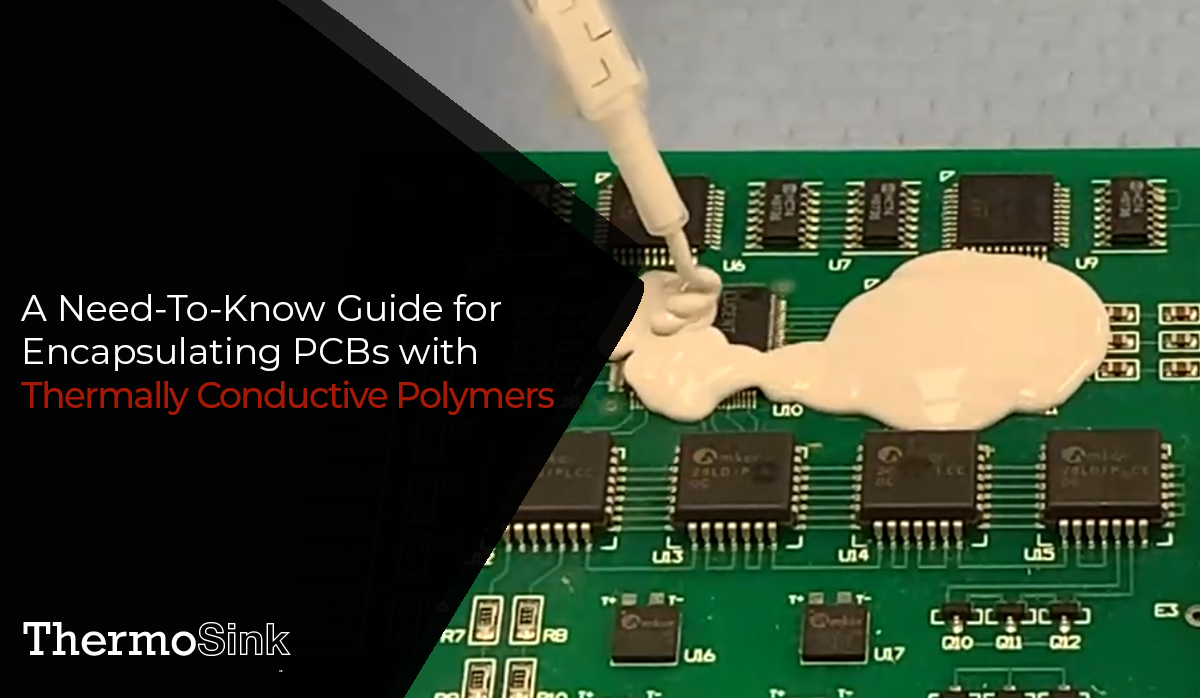

Thermally conductive polymers conduct and disperse heat away from sensitive electronics and PCB components. There are many different available chemistries for the base material which include polyethylene, epoxy, and silicone chemistries among others. The choice of polymer generally involves matching of desired temperature resistance, hardness, and flexibility among others. Since polymers are normally thermally insulative, conductivity is achieved through the use of various fillers such as metallic or halogenated compounds.

A Need-To-Know Guide for Encapsulating PCBs with Thermally Conductive Polymers

Topics: Encapsulants, Thermal Conductivity

Resin Designs Receives UL Certification for NEXUS UV800-FR Adhesive

Chase Corporation - Resin Designs division is pleased to announce that NEXUS UV800-FR adhesive has been certified as meeting V0 flame requirements under the UL94 standard. This testing completion/certification assures customers involved in the manufacture of electronics and other consumer devices that NEXUS UV800-FR is safe and appropriate for use.

Topics: Encapsulants, NEXUS UV800-FR, V0 Flame Requirements, UL94 Standard

Processing and Troubleshooting Epoxy Adhesives and Encapsulants

Two-component epoxies are versatile, viable adhesives and encapsulants that have demonstrated their value in the manufacture of electronics, medical devices, aerospace components, and many others. They provide superb electrical and mechanical properties along with the ability to resist extreme environments such as high and low temperatures and chemical exposure.

As part of our commitment to industry and customer support, we believe that our experience with two-component epoxies can be of value to manufacturers faced with certain processing and troubleshooting issues. While far from a comprehensive guide, we present below two common issues experienced when working with epoxies, as well as some tips on how to fix them.

Topics: Epoxy Adhesives, troubleshooting, Encapsulants

Cationic and free radical are the two most popular mechanisms for UV adhesives. Approximately 93% of the UV market is in free-radical chemistry while cationic has about 7%. Although a minority of the market, cationic adhesives provide strategic advantages over traditional free-radical acrylate chemistries. These advantages are detailed below.

Topics: Encapsulants, Epoxies, Cationic, UV adhesives