EMI and RFI shielding of electronic devices can be critical to their reliability and safety. Proper protection and shielding are vital in many challenging industries including aerospace, medical devices, and transportation. In addition to shielding, grounding of devices as well as protection from galvanic corrosion can extend service life and reliability. Chase Corporation has developed a unique line of preformed gasketing and shielding materials that can combine to serve the multiple functions of shielding, grounding, and corrosion resistance within a single material.

Topics: UV adhesives, EMI/RFI shielding, Gaskets, EMI shielding, RFI shielding, EMI conductive gaskets, Grounding gasket sheets, EMI gaskets, EMI gel rope gaskets

Is a UV Curable Adhesive or Coating the Right Choice for Me?

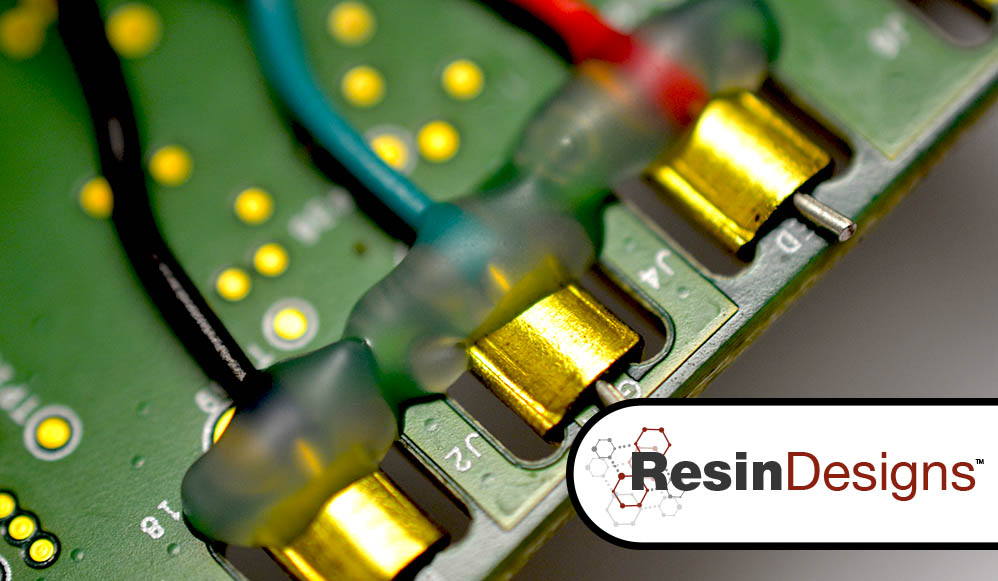

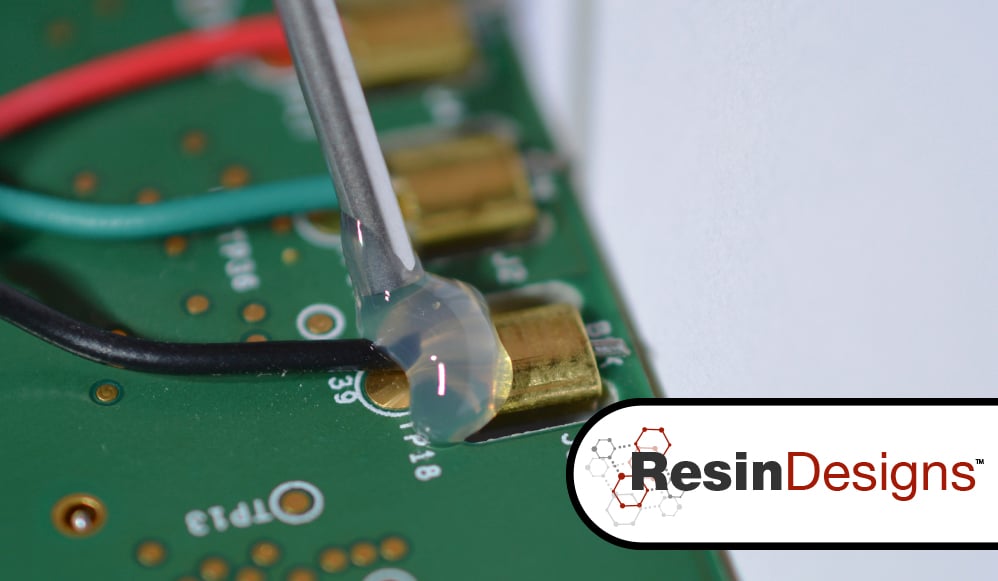

The past few decades have seen the emergence and use of ultraviolet (UV) light cured polymers across a range of industries and applications. UV cured polymers have proven their value in applications such as printing inks, adhesives, and protective coatings among others.

One of the first industries to accept and utilize UV curing polymers was the printing industry. Existing technology was mainly polymers and inks dissolved or suspended in highly flammable and hazardous solvents such as Toluene and Xylene. UV curable inks and coatings were ideally suited for this industry. Their nearly immediate curing allowed for high speeds, and their 100% solids composition often eliminated the need for pollution and fire control technology.

Topics: UV Curable (Type AR/UR), UV adhesives, UV Curing, UV light

Cationic and free radical are the two most popular mechanisms for UV adhesives. Approximately 93% of the UV market is in free-radical chemistry while cationic has about 7%. Although a minority of the market, cationic adhesives provide strategic advantages over traditional free-radical acrylate chemistries. These advantages are detailed below.

Topics: Encapsulants, Epoxies, Cationic, UV adhesives