Not all waterproofing systems perform the same under real-world stress. CIM 1000 stands apart from rigid epoxies and asphaltic coatings with its elastomeric flexibility, strong adhesion across tough substrates, and extremely low permeability. With crack-bridging up to ~400% elongation, seamless liquid-applied application, and NSF/ANSI 61 potable assemblies, CIM 1000 delivers reliable protection where competitors often fail.

Topics: Concrete Waterproofing, Water Tank

Stricter VOC rules—and the need for healthier, faster jobsites—are pushing owners to zero-VOC waterproofing. CIM’s 100% solids membranes deliver compliance without the solvent odors, while maintaining long-term, elastomeric performance and very low permeability. Use CIM ECO 1000 for zero-VOC, low-odor indoor work, CIM ECO 1061 where NSF/ANSI 61 potable approval is required, and CIM 1000 TG for vertical/overhead areas in potable assemblies—paired with moisture-tolerant, VOC-compliant primers. The result: safer installs, quicker turnarounds, and a seamless barrier that bridges cracks and handles complex details.

Topics: Concrete Waterproofing, Water Tank

Introducing CIM ECO 1061: Fast Cure, Zero VOC, Potable Water Approved.

At CIM Industries, performance and reliability have always defined our products. The latest addition to our liquid coatings line, CIM ECO 1061, not only sets a new standard for potable water protection but also for environmental sustainability. With Zero VOCs, ANSI/NSF61 potable-water approval, LEED certification, and an industry-leading

return-to-service time of 72 hours, CIM ECO 1061 enables utilities and contractors to cut downtime, accelerate project schedules, and put tanks back in operation faster.

Topics: Concrete Waterproofing, Water Tank

Choosing the right waterproofing membrane is crucial to ensuring your commercial or industrial project stands strong against water intrusion for decades. Whether protecting parking decks, water/wastewater tanks, tunnels, or plazas, understanding membrane types, applications, and specification criteria enables successful waterproofing.

This guide compares liquid-applied and sheet membranes, explains CIM’s product lineup for various substrates and environments, and shares installation and QA best practices to avoid costly errors.

Topics: Concrete Waterproofing, Water Tank

Understanding Waterproofing Warranties: Updated Guidance from CIM

Peace of mind starts with the right protection, and the right partner.

When it comes to waterproofing systems, a warranty is more than paperwork, it's a manufacturer’s formal promise that the product will perform as intended. It assures the building owner that the materials are free from defects and provides a path forward if issues arise. Most warranties are signed by both the building owner and a representative of the product manufacturer and are designed to build confidence in long-term performance and durability.

Topics: Concrete coating, CIM Industry, CIM Concrete Waterproofing, Concrete Waterproofing, Waterproofing tiles

Combatting Stormwater Erosion with Detention and Retention Tanks

Erosion occurs when winds or water interact with soil and rock, causing the affected earth to wear away. The most common example of erosion is at the beach, where tide patterns cause water to move up onto the shore and away from the shore, dragging the sand out to sea and changing the landscape.

To remedy this, communities have built retaining walls that follow parallel to the shoreline to help stop surface and subsurface erosion. While the beach may be the most thought of place where erosion occurs, it also happens onshore. Torrential downpours can wreak havoc by causing flooding and extreme soil erosion. Like beach erosion, there are ways to mitigate this issue.

Topics: Concrete Waterproofing, Water Tank

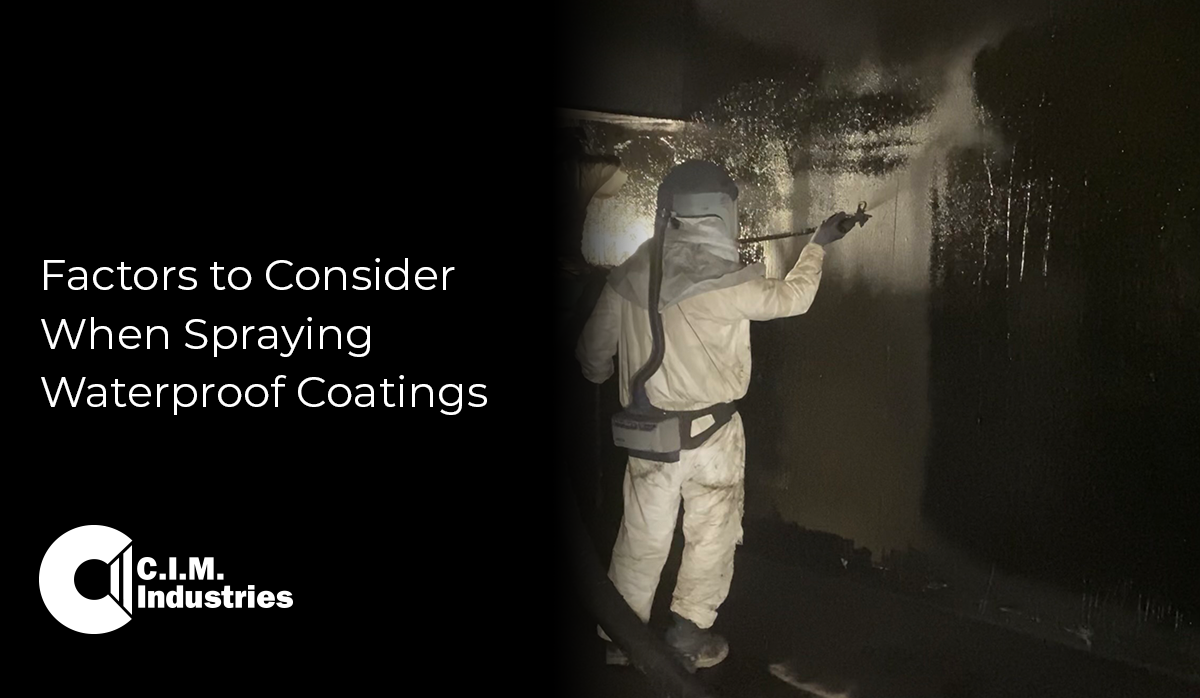

Factors to Consider When Spraying Waterproof Coatings

Industrial waterproofing projects require a specialized coating system to meet specific coating specifications. The size and scope of work will influence the application method of these coatings.

For this discussion, we will review factors to consider when spray-applying waterproof coatings on large-scale projects and the types of spray equipment needed to apply waterproofing materials. Projects with an abundance of vertical walls, overhead surfaces, and minimal risk for overspray are generally excellent candidates for utilizing spray equipment.

Typically, the spray equipment used for waterproofing products can be classified as airless, air-assisted airless, or plural component spray equipment. Always use equipment recommended by the waterproofing material manufacturer.

Topics: Concrete Waterproofing, waterproofing, Spray Applied

Selecting the Right Waterproof Coating for Leak Repairs

Let's begin by pondering this question: Why is waterproofing given less priority (left out entirely) during the pre-construction planning phase of any commercial or residential projects? This trend is truly baffling as proper waterproofing care leads to innumerable benefits in the long-term life and performance of any construction project.

Related Article: Waterproofing is the Future of Construction

Topics: Concrete Waterproofing, Liquid Applied Waterproofing, Construction

How to Successfully Apply Cold, Fluid-applied Waterproof Membranes

Cold, fluid-applied waterproofing membranes are popular choices in the construction and building industries because of their versatility in areas where traditional sheet waterproofing or hot-applied membranes are not options. Cold, fluid-applied waterproofing membranes can be applied to both vertical and horizontal surfaces and, when installed correctly, should last for many years. Understanding and following the installation guidelines will help ensure the application's success. Cold, fluid-applied waterproofing membranes’ robust physical properties and long-lasting performance are why manufacturers publish application and installation guidelines that must be followed.

Topics: CIM Industry, CIM Concrete Waterproofing, Concrete Waterproofing, Concrete Sealant, Fluid-applied Waterproof Membranes

Safety Is Top Priority When Working in Confined Spaces

The construction industry faces many safety challenges as the work environment is always changing in response to the specific job at hand. One of the most challenging environments is working within confined spaces. There are numerous safety regulations in place meant to keep construction workers safe.

Topics: CIM 1000 Premix, Concrete coating, CIM Concrete Waterproofing, Potable Water Tank, Concrete Waterproofing, CIM industries, Water Treatment

.png?width=650&height=278&name=CIM%20Chase%20logoK_301C%20(3).png)