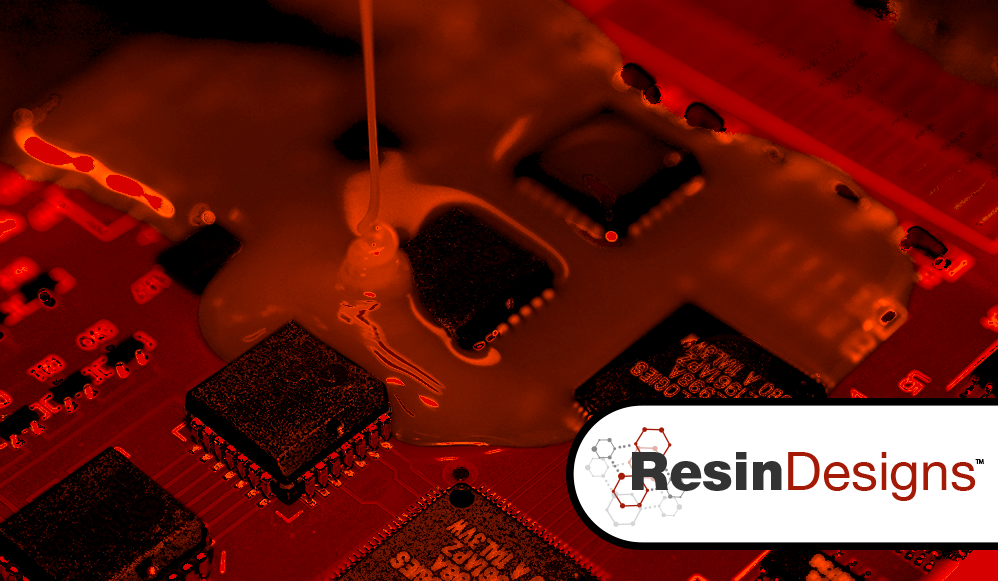

Chase Corporation - Resin Designs division is pleased to announce that NEXUS UV800-FR adhesive has been certified as meeting V0 flame requirements under the UL94 standard. This testing completion/certification assures customers involved in the manufacture of electronics and other consumer devices that NEXUS UV800-FR is safe and appropriate for use.

Resin Designs Receives UL Certification for NEXUS UV800-FR Adhesive

Topics: Encapsulants, NEXUS UV800-FR, V0 Flame Requirements, UL94 Standard

Resin Designs Promotes New, Dual-Cure Medical Adhesive AXIS 151-091

Chase Corporation through its Resin Designs division announces the promotion of AXIS 151-091, a 2-part, UV-gellable adhesive with a chemical cure mechanism. AXIS 151-091 is the most recent addition to the AXIS line of medical assembly adhesives, all of which have been designed and fully tested to meet ISO 10993-5 cytotoxicity standards.

For medical device assembly, AXIS 151-091 offers the following:

Topics: AXIS Medical Adhesives, ISO 10993-5 cytotoxicity standards.

Resin Designs Introduces Dual Cure AXIS 1064 Medical Adhesive

Chase Corporation through its Resin Designs business has announced the successful development and certification of the AXIS line of medical assembly adhesives. AXIS 1064, and all AXIS adhesives, have been designed and fully tested to meet ISO 10993-5 cytotoxicity standards.

Topics: AXIS Medical Adhesives, ISO 10993-5 cytotoxicity standards.

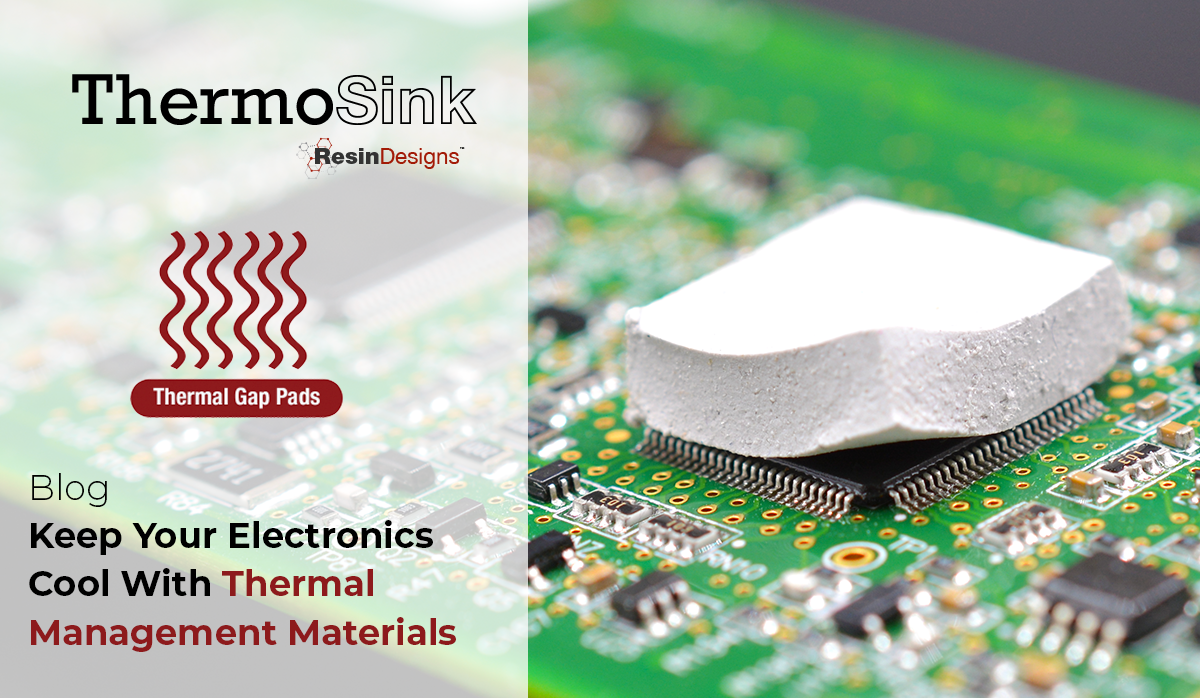

Keep Your Electronics Cool With Thermal Management Materials

Nobody likes to get too hot, and if your high-tech electronics could talk, they’d say they feel the same way. Heat is their enemy. It reduces longevity and limits reliability, two non-negotiable properties in electronics. The lack of one or both can literally mean the difference between life and death in applications such as autonomous driving and aerospace controls.

Topics: Thermal Interface Materials, Thermosink, Thermal Conductivity, Thermal Pads

Advantages of LED Curable Adhesives for Medical Device Assemblies

Medical device and componentry, ranging from needle/catheter assemblies to more complex designs, continue to explode in popularity and functionality. Recent pandemic events have, of course, contributed to a huge upsurge in urgency and demand for hypodermic needles. The call for high performance and reliability has not abated, but there is now the additional requirement for high speed and cost efficiency at a level never before seen.

Topics: Medical Adhesives, Medical Grade Adhesives, AXIS, Medical Devices

Electric Vehicles: Polymers for Performance, Reliability, & Protection

Adoption of plug in -electric vehicles (EVs) has been slower than many expected, but there is little question the next few years will see adoption accelerate. Your hypersensitive dog will have to find new visitors to harass when your delivery drivers arrive without notice, driving to your door silently in all-electric commercial vans. Many of your favorite suppliers and stores have already ordered these vehicles. Game-changing battery and charging developments are eliminating range anxiety, and autonomous driving controls and safety innovations are in the final stages of building our trust.

Topics: Thermal Interface Materials, Vibration Suppression, Thermosink, Conformal coating benefits, EMI conductive gaskets, EV, Electric Vehicle

Protective Coatings and Polymers for Hydrogen Fuel Cell Electronics

Modern hydrogen fuel cell technologies require ever more sophisticated and reliable electronic control systems to assure both safety and longevity. Hydrogen fuel cells are gaining in popularity in critical industries including automotive, aerospace, ocean transportation, military, and power microgrid systems among others. Protection of printed circuit boards and their components from physical, chemical, and thermal damage is essential to produce robust and reliable fuel cell systems for demanding applications.

EMI and RFI shielding of electronic devices can be critical to their reliability and safety. Proper protection and shielding are vital in many challenging industries including aerospace, medical devices, and transportation. In addition to shielding, grounding of devices as well as protection from galvanic corrosion can extend service life and reliability. Chase Corporation has developed a unique line of preformed gasketing and shielding materials that can combine to serve the multiple functions of shielding, grounding, and corrosion resistance within a single material.

Topics: UV adhesives, EMI/RFI shielding, Gaskets, EMI shielding, RFI shielding, EMI conductive gaskets, Grounding gasket sheets, EMI gaskets, EMI gel rope gaskets

What Is the Glass Transition Temperature (Tg) of a Polymer

image: Plastic transitioning from solid to amorphous

One of the most common terms that you hear when discussing polymers used as adhesives and coatings is the “glass transition temperature” (often abbreviated Tg). This property is in fact one of the most critical to consider when choosing the correct material for your application. Since many of us never got further than high school physics and chemistry, this term can be a little confusing and deserves explanation.

A layman’s definition of the glass transition temperature of a polymer is the temperature at which an amorphous polymer moves from a hard or glassy state to a softer, often rubbery or viscous state.

Topics: Epoxy Adhesives, Glass Transition, Adhesive Solutions, Polymers, Curable Adhesive, Glass Transition Temperature

Processing and Troubleshooting Epoxy Adhesives and Encapsulants

Two-component epoxies are versatile, viable adhesives and encapsulants that have demonstrated their value in the manufacture of electronics, medical devices, aerospace components, and many others. They provide superb electrical and mechanical properties along with the ability to resist extreme environments such as high and low temperatures and chemical exposure.

As part of our commitment to industry and customer support, we believe that our experience with two-component epoxies can be of value to manufacturers faced with certain processing and troubleshooting issues. While far from a comprehensive guide, we present below two common issues experienced when working with epoxies, as well as some tips on how to fix them.

Topics: Epoxy Adhesives, troubleshooting, Encapsulants

%20of%20a%20Polymer%2c%20and%20Why%20Does%20It%20Matter%20to%20Me%3F.jpg)