The past few decades have seen the emergence and use of ultraviolet (UV) light cured polymers across a range of industries and applications. UV cured polymers have proven their value in applications such as printing inks, adhesives, and protective coatings among others.

One of the first industries to accept and utilize UV curing polymers was the printing industry. Existing technology was mainly polymers and inks dissolved or suspended in highly flammable and hazardous solvents such as Toluene and Xylene. UV curable inks and coatings were ideally suited for this industry. Their nearly immediate curing allowed for high speeds, and their 100% solids composition often eliminated the need for pollution and fire control technology.

Read More

Topics:

UV Curable (Type AR/UR),

UV adhesives,

UV Curing,

UV light

Axis 310 and Axis 310-W are the most recent additions to Resin Designs’ growing line of medically tested and qualified adhesives. Both products are single component epoxies for simplicity in application. Their heat curing chemistry provides added temperature and chemical resistance properties. These adhesives bond to a wide range of substrates typically found in the design of high-performance medical devices.

Read More

Topics:

Resin Designs,

Adhesive Solutions,

Curable Adhesive

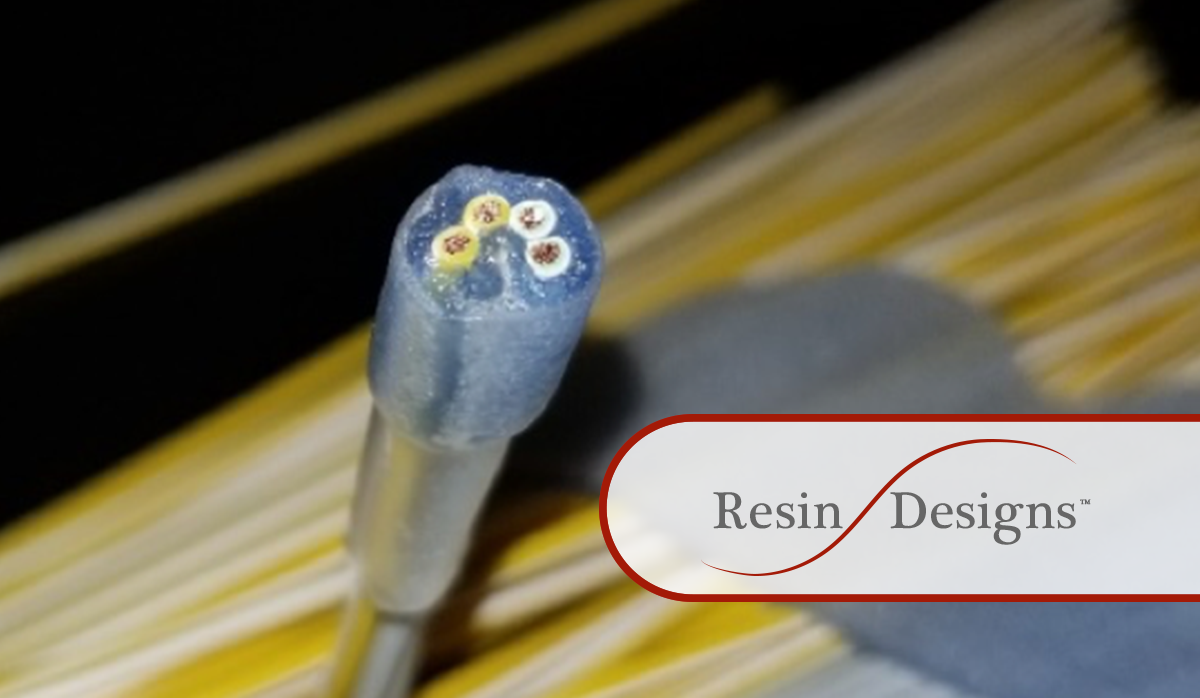

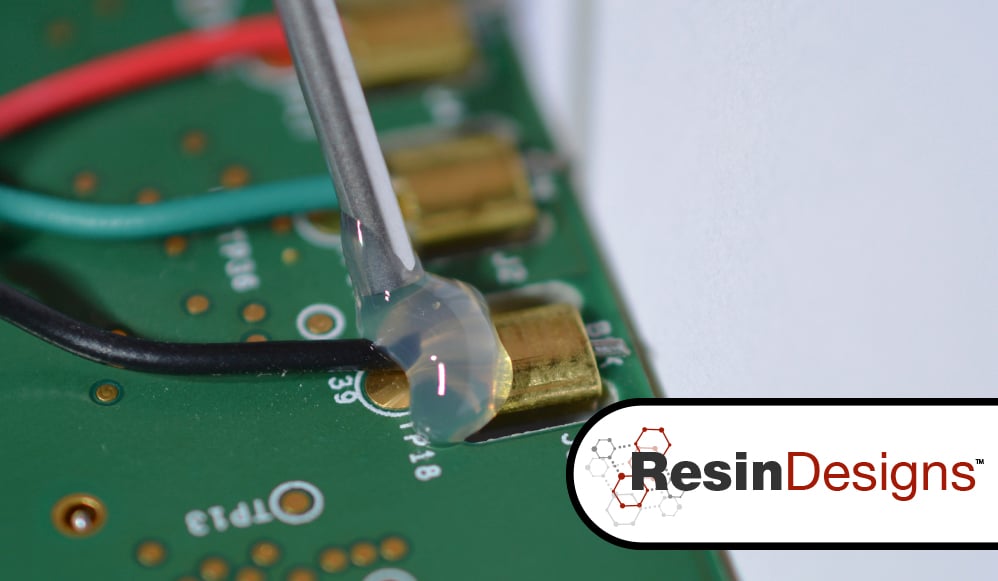

In our previous blog we introduced one of our products GT-1030 as an effective solution to problems related to sealing and protecting wire bundles and harnesses. In this blog, we will provide a step-by-step process in how to effectively waterproof small wire bundles.

Read More

Topics:

cable waterproofing,

waterproofing silicones,

waterproofing

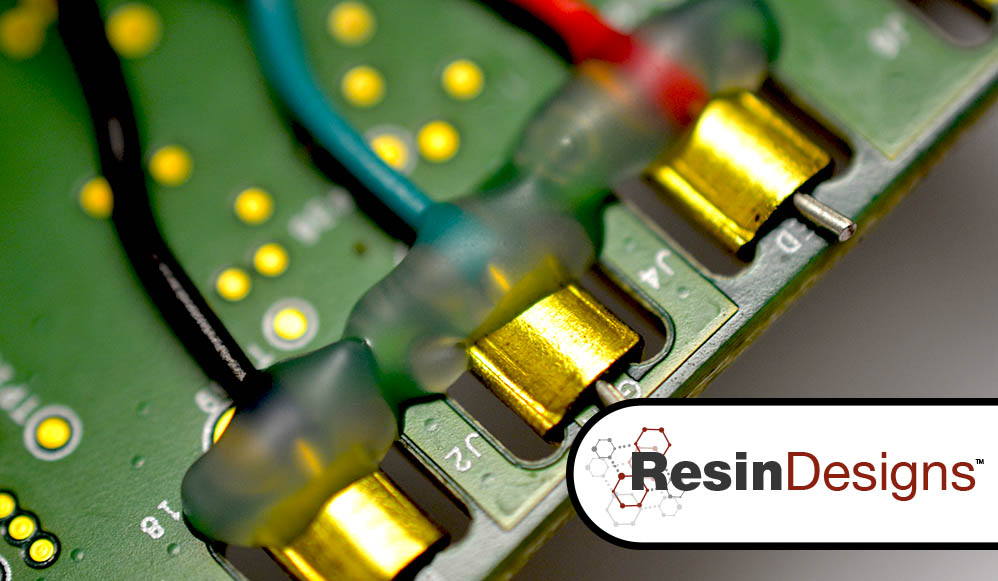

Resin Designs receives regular inquiries regarding products that can seal wire bundles, harnesses and connectors. Market sectors and applications vary from automotive connectors to consumer appliances, LED connectors/housings in lighting industries as well as directional drilling cables in gas and oil exploration. Below are examples of the inquiries:

Read More

Topics:

cable waterproofing,

waterproofing silicones,

waterproofing

Millimeter-wave (mmWave) radar technology has emerged as an accurate and cost-effective approach to motion sensing and control. Resin Designs’ TechFilm B-Stage Epoxies (electrically conductive and structural) have been enhancing the performance of these devices. With their precise bond line thickness and placement accuracy, the B-stage epoxy films play critical roll in ground plane formation and adhesion of patch antenna to power boards. The technology has been front and center in the automotive arena from basic safety innovations like back up and side sensing devices to full autonomous driving development. As mmWave devices increase in number within an automobile, a number of key factors are driving development including:

Read More

Topics:

b-Stage Epoxy,

MMWave Technology,

Autonomous cars,

Radar technology

Cationic and free radical are the two most popular mechanisms for UV adhesives. Approximately 93% of the UV market is in free-radical chemistry while cationic has about 7%. Although a minority of the market, cationic adhesives provide strategic advantages over traditional free-radical acrylate chemistries. These advantages are detailed below.

Read More

Topics:

Encapsulants,

Epoxies,

Cationic,

UV adhesives

Resin Designs UV 165-183 is uniquely designed for thick applications as both an adhesive and encapsulant where UL V0 fire ratings are critical. The products properties include:

Read More

Topics:

Resin Designs,

Adhesive Solutions,

Curable Adhesive

B-stage epoxy films for clean reliable bonding/thermal and electrical conductivity

Most of us are familiar with epoxy adhesives and coatings, especially those of us within the electronics and medical device industries. We have all seen and often used two-component liquid epoxies. They are provided in syringes or pails for dispensing as adhesives, sealants, gaskets, and coatings. There is, however, a lesser known relative that can be cleaner, more consistent, environmentally friendly, and capable of unique properties such as thermal and electrical conductivity. It is known as B-stage epoxy film.

Read More

Topics:

Adhesive Solutions,

b-Stage Epoxy,

Techfilm

Thermally conductive silicone products are widely used in the electronics industry to radiate heat away from locales for component survivability while maintaining optimum operating temperatures. For potting and encapsulation applications, circuit board engineers typically specify flowable products that will quickly surround the components after dispensing and become solid at room temperature within an hour or less.

Read More

Topics:

Resin Designs,

Thermosink,

Thermal Conductivity,

Potting Material

Concerned about the long-term reliability of dispensed, non-curing thermal interface solutions? What about cracking and pump-out that increase thermal resistance after aging and thermal shock? These are just a few of many important reasons to consider using pre-cured pads as a thermal transfer medium between a heat spreader and electrical components over wet-dispensed products that are prone to failure over time as in the example provided below.

Read More

Topics:

Thermal Interface Materials,

Thermoplastic