Dan Griffin

HumiSeal Midwest Account Manager

The transition to LED curable conformal coatings is beginning to build momentum, beginning as a slow evolution and developing into a revolution of sorts. The driving forces behind this include:

- Improved processing equipment designs and availability

- Aging or outdated application equipment replacements

- Increasing range of LED curables commercially available or in development

- Rising labor, equipment, and energy costs

If you and your organization are faced with aging equipment and higher costs, there isn't a better time to consider the potential advantages of LED curable conformal coatings!

Read More

Topics:

conformal coating,

Protection for PCB,

UV Curing,

LED curable conformal coating

Chase Corporation, through our HumiSeal® and Resin Designs divisions, has spent the past decade preparing protection and reliability solutions for complex electronics. Notably, within the emerging EV market, we have identified needs within the assembly of EV motors where superior adhesion and protection are particularly critical.

Read More

Topics:

Epoxy Adhesives,

EV,

Electric Vehicle,

HumiSeal 2E25

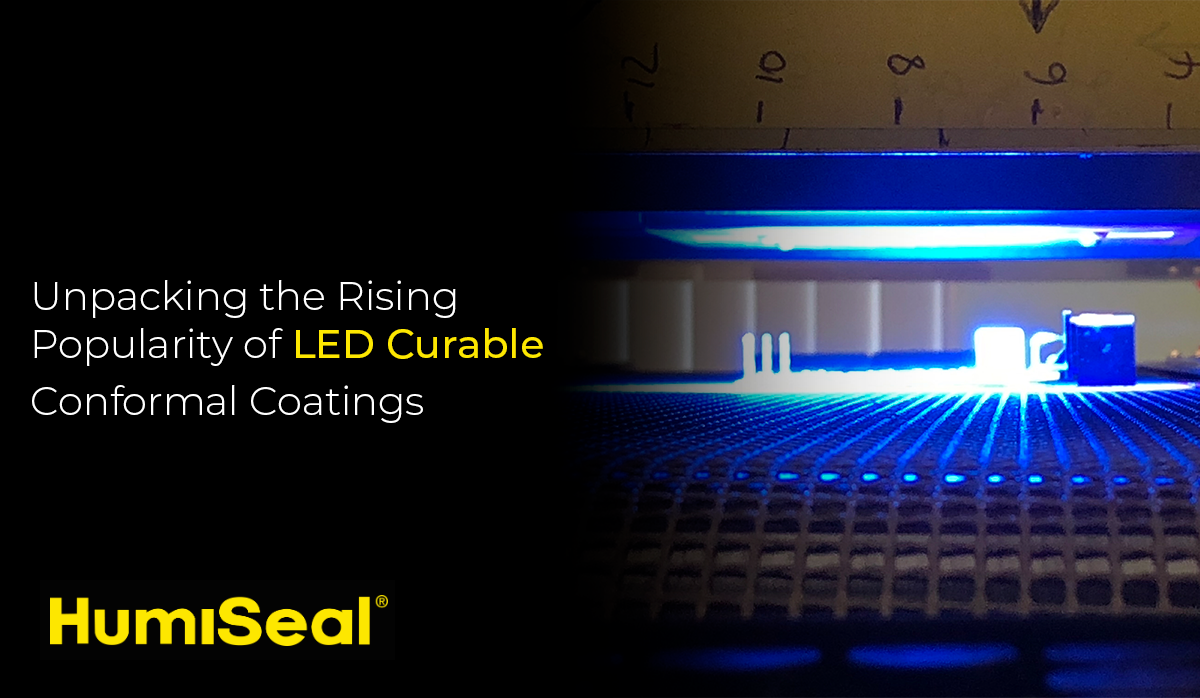

Conformal coating with parylene is a very different process compared to coating with traditional solvent-borne or UV curable materials. Parylene coating has some advantages including

- a very thin application profile,

- uniform and complete surface coverage, and

- generally excellent protection and minimal outgassing potential.

On the other hand, parylene coating also presents unique challenges such as

- a significant investment in complex equipment,

- batch processes that limit productivity and increases costs, and

- the user’s inability to selectively control where the coating is applied.

It is this final challenge that we will concern ourselves with within the following discussion.

Read More

Topics:

Masking,

UV92,

Parylene Conformal Coating,

Parylene process

Most anyone over the age of 30 has probably seen Back to the Future and remembers Marty McFly. One line of Marty’s that inexorably drew him into ill-advised actions was the classic “Nobody calls me yellow.” Nothing good comes from yellow, and this turns out to be just as applicable in LCD screen manufacture as it was in the movie.

Read More

Topics:

LCD displays,

LOCA,

Liquid Optically Clear Adhesives,

Yellowing

You have a lot of options regarding the packaging of your adhesives and coatings. In this blog installment, we will discuss characteristics, advantages, and concerns regarding one of the more unique alternatives: Bladder Bags

Read More

Topics:

Conformal Coating Packaging,

Bladder Bag

Conformal coatings rose to prominence in protection of printed circuit boards (PCBs) about five decades ago. Through their use, early PCB failures due to dust and dirt, liquids, and humidity contamination were greatly reduced or eliminated. This in turn allowed for the longer warranties and improved reliability we see today. Early conformal coatings, many of which are still in use today, were comprised of polymers dissolved in various solvents such as MEK, toluene, or xylene.

An approximate evolution of conformal coating chemistries could be viewed as

- solvent-borne acrylics and polyurethanes

- waterborne acrylics

- synthetic rubber coatings

- UV-curable acrylated urethanes

- LED UV-curable acrylated urethanes

Read More

Topics:

conformal coating,

LED technology,

Eco-friendly,

LED curable conformal coating

March 4th of 2020 represented a potentially seminal date for both suppliers and manufacturers within the printed circuit board industry. This was the date of release of four updated Guobiao or “GB” standards related to the VOC content and other harmful substances allowable within supplied inks, adhesives, and protective coatings in China. This change in regulations is the result of China’s three-year action plan begun in 2018. The plan is intended to improve air quality through reduction of VOC emissions by at least 10% as compared to 2015 levels.

The new standards are straightforward but can become difficult to understand as they are often implemented by city and by region.

Read More

Topics:

Low VOC Applications,

VOC China,

LTX Coatings,

GB standards,

VOC emissions,

Sustainability

Packaging. Not the most complex subject when choosing a conformal coating, but treat the decision too lightly at your peril. There are a surprising number of options available, each suitable to very specific needs and conditions. In this brief presentation we will discuss, from smallest to largest, the various packaging choices available to you, along with the advantages and disadvantages of each.

Read More

Topics:

conformal coating,

Conformal Coating Process,

Conformal Coating Packaging

Take a quick look at the photograph on your right. If you are in the business of PCB manufacturing with conformal coatings, does it frighten or concern you at all? Does the magnified coating appear to truly “conform” to the surfaces evenly? And if not, what effect, if any, might this have on the protection of your PCBs?

First of all, don’t panic. What you see in the photograph is not unusual and is not necessarily a problem. It is important, however, that if you are in the business of applying conformal coatings, you should have a clear understanding of some of the unique challenges they present.

Read More

Topics:

conformal coating,

silicone conformal coating,

Humiseal,

Conformal Coating Process

UV curable conformal coatings have attained widespread use in applications requiring fast through-put times, such as automotive, white goods, and industrial control manufacturing. In addition to speed of cure, UV curable conformal coatings provide the advantage of high physical protection and chemical resistance for electronic systems. Traditionally the UV curing of coatings is an energy intensive process. One that uses high-power mercury discharge lamps, which as a result of use produce considerable amounts of heat and ozone. The recent introduction of new, high-output LED UVA light units allows for the successful cure of conformal coatings by using between 365nm and 395nm wavelength of UVA light, effectively curing with minimal heat and no ozone generation.

Read More

Topics:

UV Curable (Type AR/UR),

Conformal Coating Process,

conformal coating application,

UV Curing,

UV light,

UVA