In the days before surface mount printed circuit assemblies, components (such as resistors, diodes, and capacitors) were axial, and printed circuit board components were installed with the “through-hole” method using large conductor spacing. With the advent of integrated circuits, these too were through-hole with good spacing between legs.

To Clean or Not To Clean Before Conformal Coating

Topics: Cleaning process, Protection for PCB

The Next Stage of Total PCB Protection: Sharp Edge Conformal Coatings

We at HumiSeal are no strangers to conformal coatings; and if you’re reading our blogs, it’s likely you’re familiar with these coatings as well. The word “conformal” is descriptive of the function of the coatings which are expected to spread and conform evenly across all surfaces that are to be protected. This uniform and even distribution is necessary to protect delicate electronic components from things such as humidity, water, vibrations, and thermal damage (to name a few).

Topics: Conformal Coatings, Conformal Coating Troubleshooting, Sharp Edge

Don’t Overlook Clean, Dry Air When Using Conformal Coatings

We at HumiSeal would like to dedicate a bit of time and space to one of the most often ignored factors related to successful conformal coating processes: Clean Air.

Topics: Protection for PCB, air quality

Optimizing UV and LED Curing Ovens with Radiometers

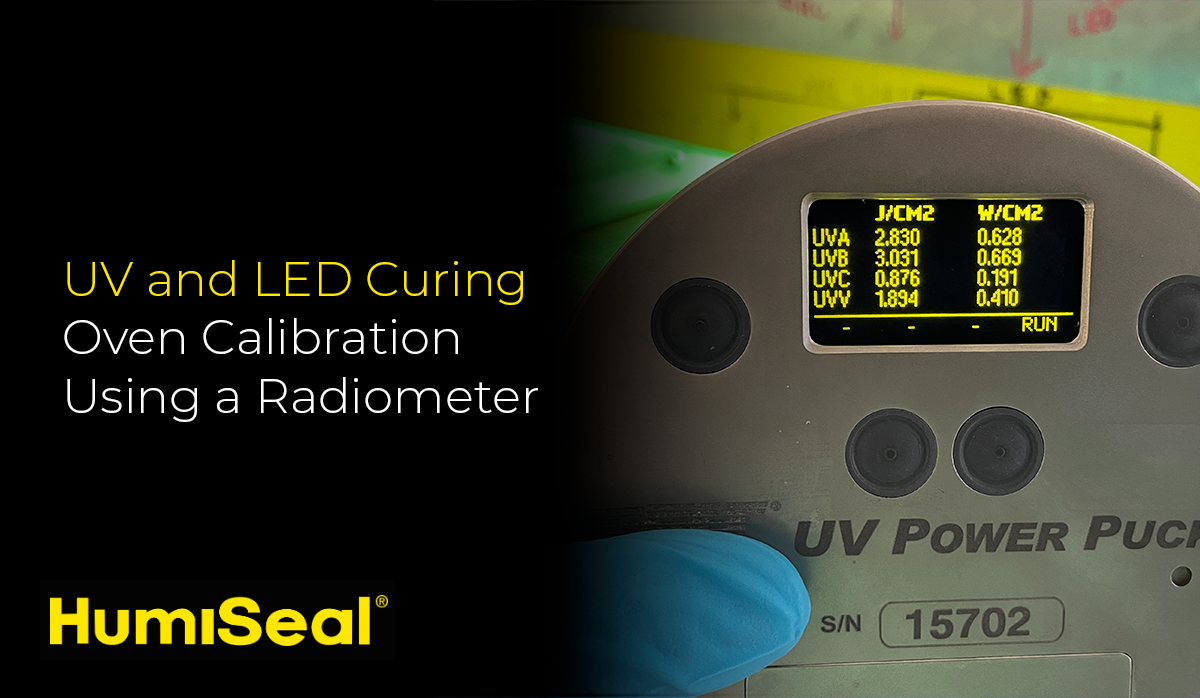

We recently published a blog outlining radiometer configuration and usage. Give it a read if you missed it! Since you’re now an expert at operating your radiometer, this blog will look at the steps needed to optimize your UV or LED oven.

This process is practically as simple as increasing and decreasing the UV or LED cure system’s conveyor speed to affect the dose. You must also consider increasing and decreasing the distance between the cure system’s lights and the radiometer to achieve at least the minimum irradiance required per the coating, adhesive or GELS technical data sheet.

One further note regarding LED cure systems is to ensure you’re using a light source that not only has the correct power (Watts), but also emits UV energy in the correct wavelength.

How to Calibrate a UV or LED Curing Oven

Topics: UV Curing, LED curable conformal coating, Radiometer

UV and LED Curing Oven Calibration Using a Radiometer

It's 2023; the electronics industry is embracing UV-curable coatings. There are many valid reasons for this, from the desire to reduce/eliminate VOCs, difficulty navigating ever-changing and complex environmental regulations, increasing energy and labor costs as well as the sheer volumes modern assembly lines must increasingly meet.

Topics: UV Curing, LED curable conformal coating, Radiometer, PowerPuck

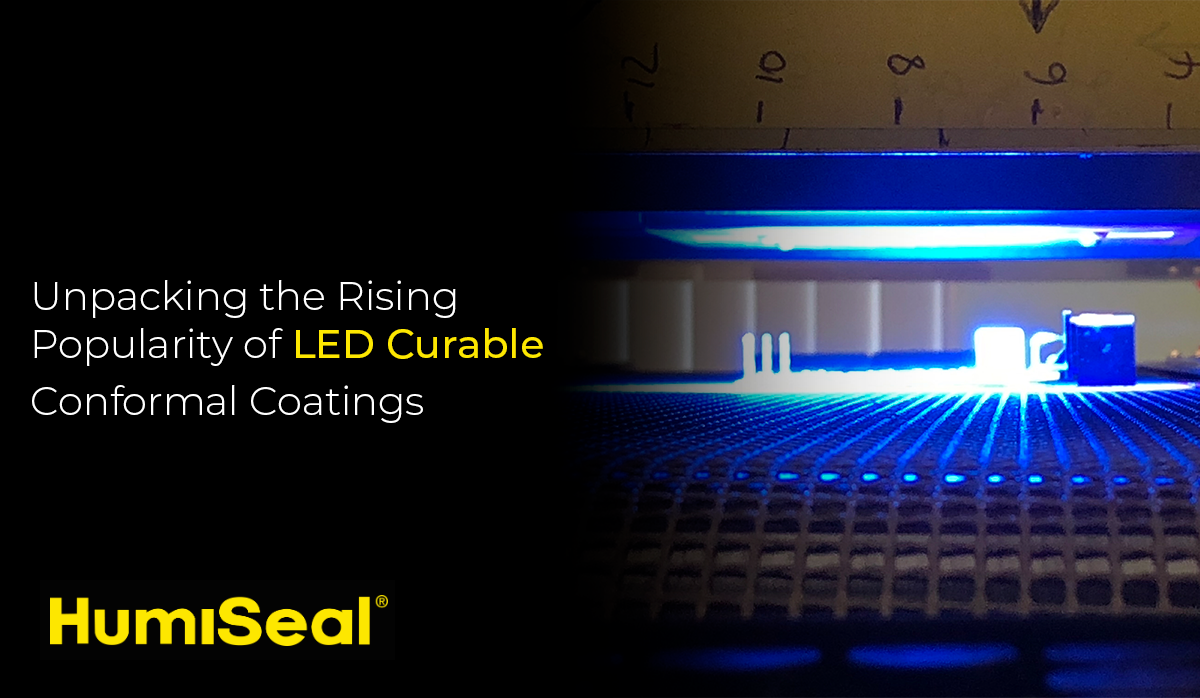

Unpacking the Rising Popularity of LED Curable Conformal Coatings

The transition to LED curable conformal coatings is beginning to build momentum, beginning as a slow evolution and developing into a revolution of sorts. The driving forces behind this include:

- Improved processing equipment designs and availability

- Aging or outdated application equipment replacements

- Increasing range of LED curables commercially available or in development

- Rising labor, equipment, and energy costs

If you and your organization are faced with aging equipment and higher costs, there isn't a better time to consider the potential advantages of LED curable conformal coatings!

Topics: conformal coating, Protection for PCB, UV Curing, LED curable conformal coating

Get the Best Results When Manual Brushing Conformal Coatings

Manual brushing is just one of many methods commonly used for applying conformal coating materials to PCBs and other components. It is a hand-applied method that requires little investment into automation or equipment. With practice, it can be one of the simplest methods available, especially for small-batch production or isolated applications.

Topics: Conformal Coatings, conformal coating application, Manual Brush

Complete Guide to Viscosity Part 2: Measurements and Devices Explained

This blog is the second installment in our two-part series on viscosity (with special consideration on adhesives and coatings).

In our previous viscosity blog, we discussed the properties of viscosity and how viscosity can be affected by temperature, the addition of dilution or thinning agents, and other similar factors.

Topics: conformal coating, viscosity

Adhesives for Electric Vehicle Motors: Performance and Protection

Chase Corporation, through our HumiSeal® and Resin Designs divisions, has spent the past decade preparing protection and reliability solutions for complex electronics. Notably, within the emerging EV market, we have identified needs within the assembly of EV motors where superior adhesion and protection are particularly critical.

Topics: Epoxy Adhesives, EV, Electric Vehicle, HumiSeal 2E25

HumiSeal® UV20Gel: Durability and Reliability for PCBs Under Thermal Stress

HumiSeal UV20Gel is a unique, strong, and flexible gel coating developed to protect PCB (Printed Circuit Boards) components against environmental conditions and vibrations. UV20Gel has proven successful in many demanding industries and product families including-

HumiSeal UV20Gel is a unique, strong, and flexible gel coating developed to protect PCB (Printed Circuit Boards) components against environmental conditions and vibrations. UV20Gel has proven successful in many demanding industries and product families including-

Topics: Electronic Protection, Vibration Suppression, Thermal Compatibility, Protection for PCB, Thermal Stress Testing