Durable Protection for Demanding Automotive Requirements

HumiSeal chemists have been designing state-of-the-art conformal coatings for nearly 70 years, first producing UV curable coatings more than two decades ago. At that time, UV curable technology was considered the next generation of coatings, mainly due to its advantages; including:

Read More

Topics:

UV Curable (Type AR/UR),

Humiseal,

Thermal Conductivity,

Conformal Coating Costs,

Autonomous cars,

Car interior

Counterfeits exist. Our industry is no exception. We’ve pointed out counterfeit conformal coatings on two separate occasions, but it is time to do so again. Unlike most electronics components, damage attributed to counterfeit conformal coatings is often unreported as it can be challenging to tell the difference between counterfeit brands and the original coating. The best way to protect yourself against this is to purchase directly from HumiSeal or one of our authorized channel providers.

Read More

Topics:

conformal coating,

Humiseal Blog,

counterfeit,

Conformal Coating Costs

This is the first in a short series on material viscosity, in which we will review what it is and how to measure it. We will start with the definition of viscosity. Viscosity is the internal friction of moving fluid and a measurement of the resistance of a fluid deformed by shear stress. It is measured in centiPoise. The lower the number, the less viscous the material, as can be seen by this comparison chart: starting with water at 1 cPs and ending with honey at anywhere between 2,000 – 10,000 cPs.

Read More

Topics:

conformal coating,

Coating Application Preparation,

conformal coating application,

viscosity,

Humiseal Blog

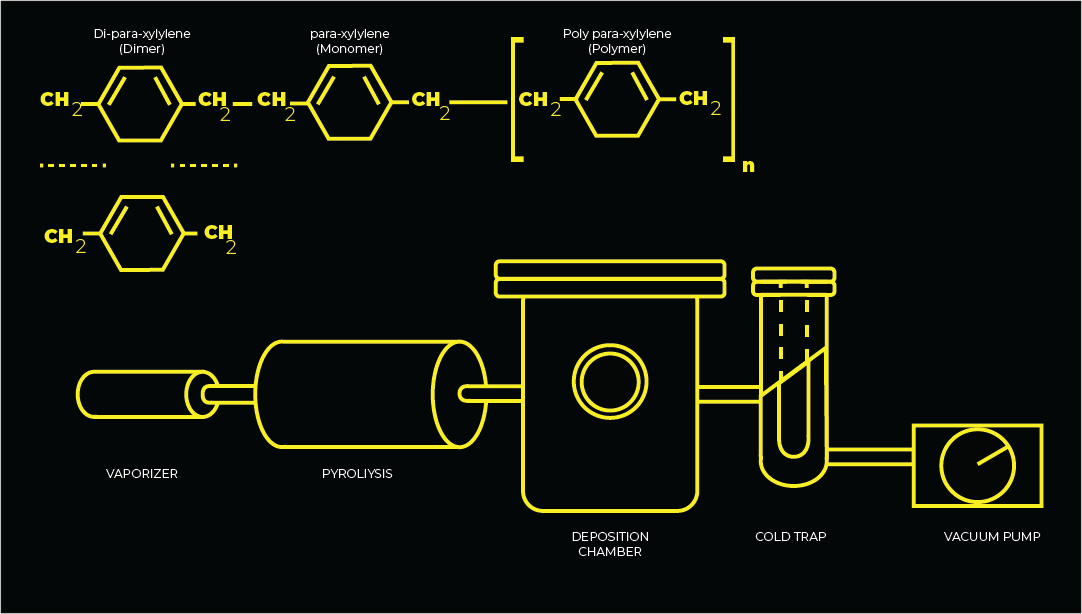

Conformal coating with parylene is a very different process compared to coating with traditional solvent-borne or UV curable materials. Parylene coating has some advantages including

- a very thin application profile,

- uniform and complete surface coverage, and

- generally excellent protection and minimal outgassing potential.

On the other hand, parylene coating also presents unique challenges such as

- a significant investment in complex equipment,

- batch processes that limit productivity and increases costs, and

- the user’s inability to selectively control where the coating is applied.

It is this final challenge that we will concern ourselves with within the following discussion.

Read More

Topics:

Masking,

UV92,

Parylene Conformal Coating,

Parylene process

Most anyone over the age of 30 has probably seen Back to the Future and remembers Marty McFly. One line of Marty’s that inexorably drew him into ill-advised actions was the classic “Nobody calls me yellow.” Nothing good comes from yellow, and this turns out to be just as applicable in LCD screen manufacture as it was in the movie.

Read More

Topics:

LCD displays,

LOCA,

Liquid Optically Clear Adhesives,

Yellowing

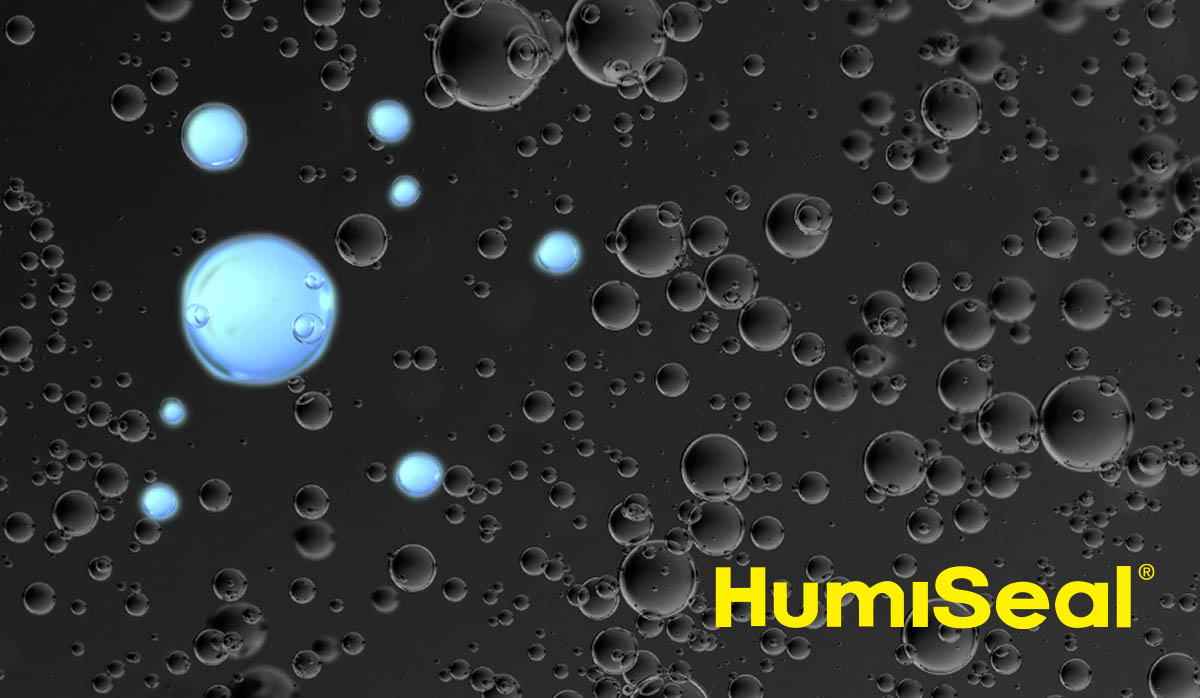

During the assembly process, the use of a liquid optically clear adhesive (LOCA) is important for ideal visual properties in LCD screen manufacture. The assembly process has evolved and advanced, but there are still potential weaknesses or defects that must be taken into account in both adhesive selection and process design. In this blog installment, we will discuss one of these potential defects: entrapped bubbles.

Read More

Topics:

Display Adhesives,

LCD displays,

LOCA,

Liquid Optically Clear Adhesives

Haze and lack of clarity are considered among the most vexing and stubborn of defects in the assembly of LCD screens and surfaces. Significant advances have been made in the optical quality and capability of liquid crystals and LEDs; however, these advances can be stunted by choices made further along in the assembly process. Specifically, liquid optically clear adhesives (LOCAs) used in the bonding of assembly layers can cause haze and light refraction either immediately or under certain aging conditions. The proper design of LOCA materials must take this risk of haze development into consideration. There are a number of effective approaches to minimizing or eliminating haze.

Read More

Topics:

Humiseal,

Adhesive Solutions,

Display Adhesives,

LOCA,

Liquid Optically Clear Adhesives

You have a lot of options regarding the packaging of your adhesives and coatings. In this blog installment, we will discuss characteristics, advantages, and concerns regarding one of the more unique alternatives: Bladder Bags

Read More

Topics:

Conformal Coating Packaging,

Bladder Bag

UV20GEL is a recent innovation from the polymer scientists at HumiSeal.

It provides additional durability and ruggedization for printed circuit boards in demanding applications including automotive, aerospace, and appliances among others. This flexible, high adhesion gel is used for staking taller or sensitive components to provide resistance to vibration and mechanical shock conditions.

Read More

Topics:

Electronic Protection,

Vibration Suppression,

UVGEL,

Mechanical Shock

Conformal coatings rose to prominence in protection of printed circuit boards (PCBs) about five decades ago. Through their use, early PCB failures due to dust and dirt, liquids, and humidity contamination were greatly reduced or eliminated. This in turn allowed for the longer warranties and improved reliability we see today. Early conformal coatings, many of which are still in use today, were comprised of polymers dissolved in various solvents such as MEK, toluene, or xylene.

An approximate evolution of conformal coating chemistries could be viewed as

- solvent-borne acrylics and polyurethanes

- waterborne acrylics

- synthetic rubber coatings

- UV-curable acrylated urethanes

- LED UV-curable acrylated urethanes

Read More

Topics:

conformal coating,

LED technology,

Eco-friendly,

LED curable conformal coating

.png)