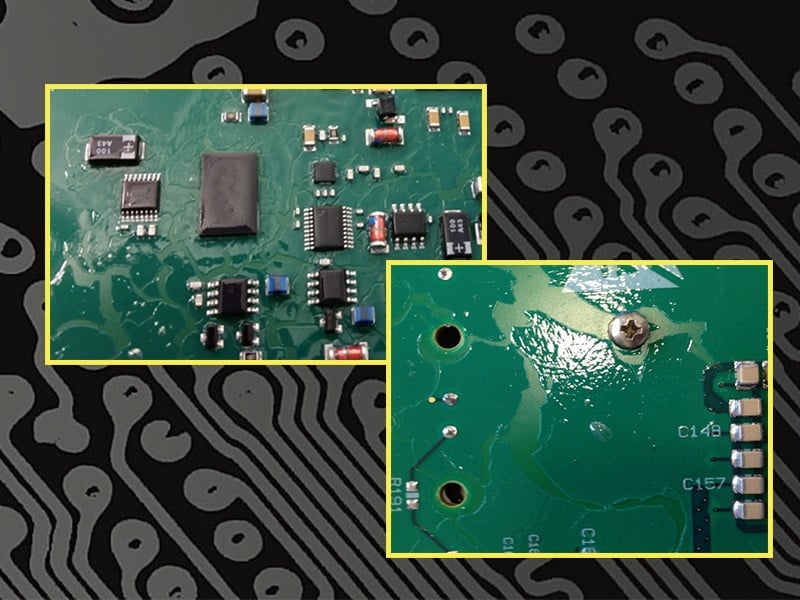

The application of the conformal coating in a uniform and consistent coverage is a key challenge that defines the reliability of the finished product.

A thin coating will provide inadequate protection against corrosion or insulation between conductors. Conversely, if the conformal coating is too thick, it will increase the risk of forming other types of coating defects such as bubbles, insufficient curing, and potential cracking during thermal shock cycles.

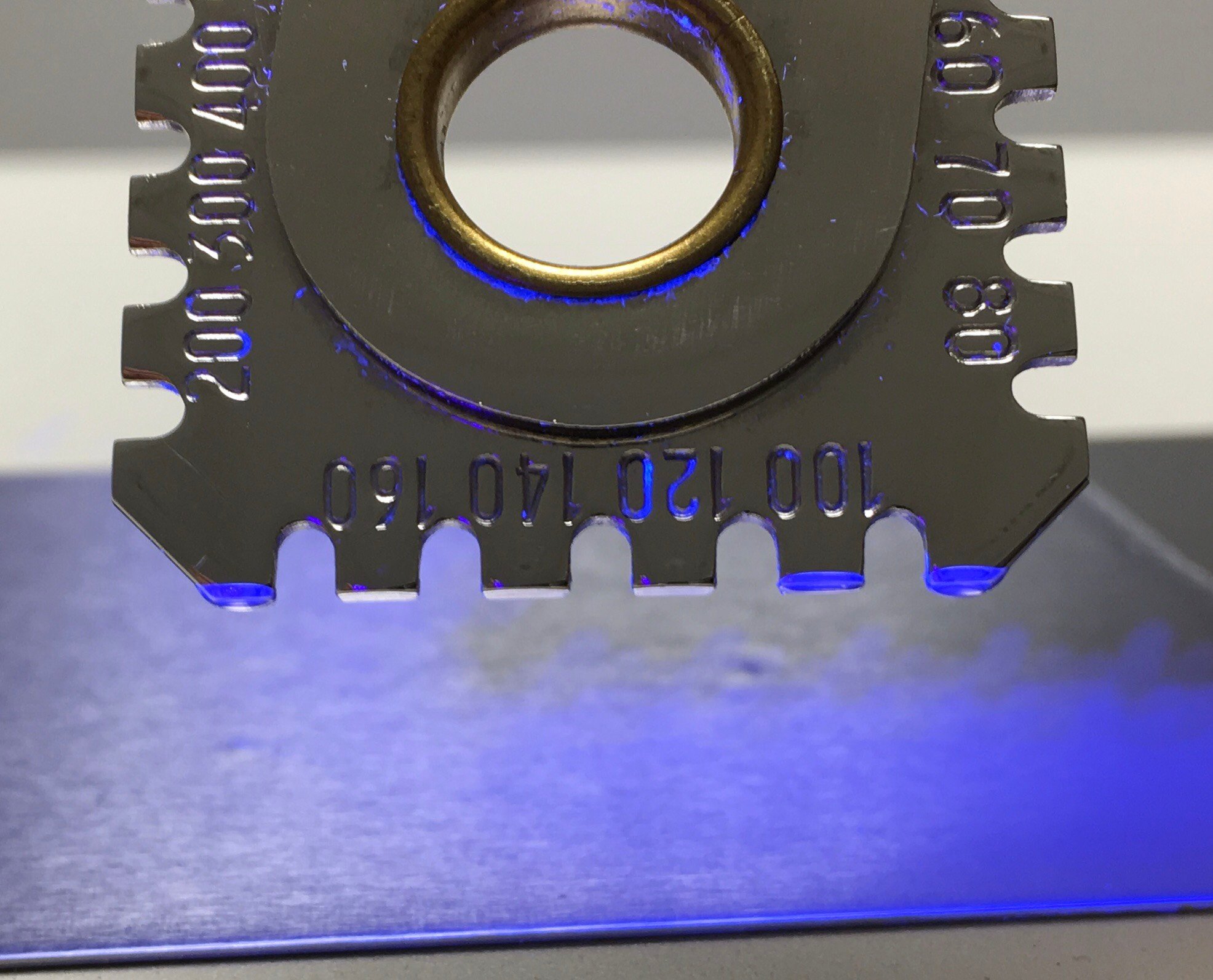

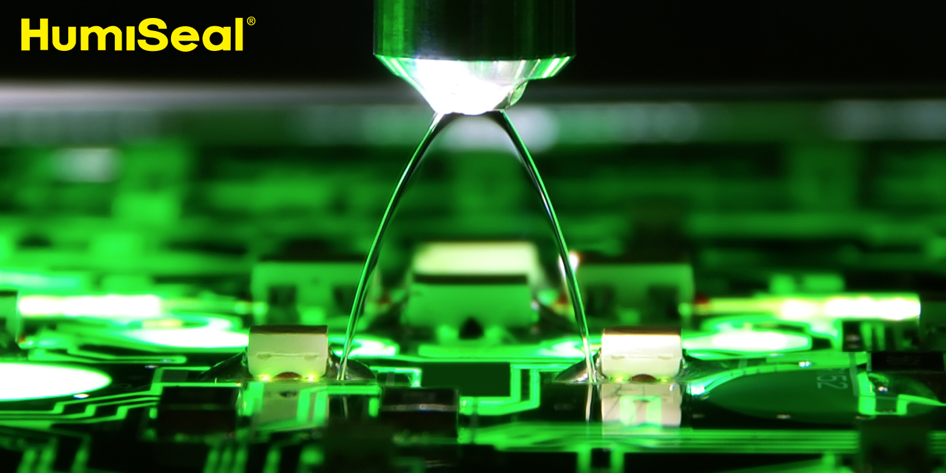

Besides the verification of the process parameters such as coating viscosity and the application method is correctly setup, the amount of conformal coating material applied on the printed circuit boards can be measured before curing. For this, wet film conformal coating thickness gauges are used. This method ensures quality control while the coating material is still wet.